The use of PCM in substations has several advantages. First, PCM can provide better power quality than traditional methods. Second, PCM is more efficient and can reduce energy costs.

Third, PCM is more reliable and can improve the overall performance of the substation. Finally, PCM is easier to maintain and can extend the life of the substation equipment.

There are many reasons to use PCM in a substation. First, it can help improve the reliability of the power system by providing redundancy and diversity. Second, it can help reduce costs by eliminating the need for multiple transformers and other equipment.

Third, it can improve the efficiency of power transmission and distribution by reducing line losses. Finally, it can provide better voltage regulation and load balancing.

What's the difference between an ECM, TCM, and PCM?

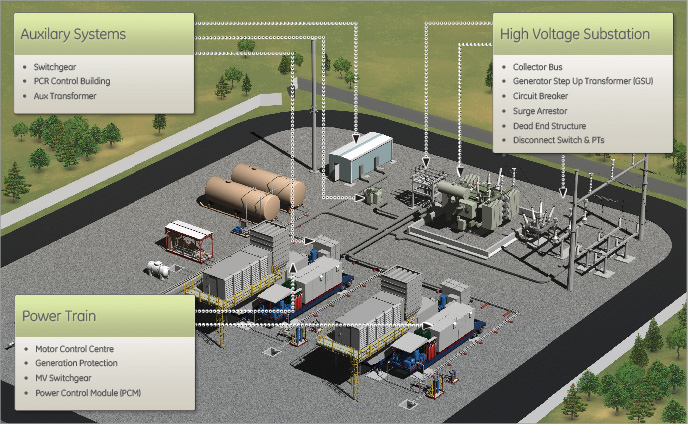

Credit: www.gegridsolutions.com

1)What is the Purpose of Using Pcm in Substations

2) What are the benefits of using PCM in substations?

3) How does PCM work in substations?

1) The purpose of using PCM in substations is to help reduce the overall size of the substation.

This is because PCM takes up less space than other types of equipment. Additionally, PCM can help improve the efficiency of the substation by reducing losses and increasing capacity.

2) The benefits of using PCM in substations include its ability to take up less space, improve efficiency, and reduce losses.

Additionally, PCM can also help with power quality issues by providing clean energy to the grid.

3) How does PCM work in substations? When used in a substation,PCMs are typically installed between the high-voltage busbars and low-voltage transformers or loads.

In this way, they can act as impedance matching devices that provide voltage transformation and current limiting capabilities.

Conclusion

There are many benefits to using a PCM in a substation. First, it can help to improve the reliability of the power system by providing protection against faults. Second, it can help to reduce the cost of operation and maintenance by reducing the need for manual intervention.

Third, it can help to improve the quality of service by reducing the time required for repairs and increasing the availability of power. Finally, it can help to improve safety by reducing the risk of fire and explosions.