A substation is a location where electricity is generated, transformed and distributed to consumers. A substation must have the following:

-A power source such as a generator or transformer

-High voltage equipment such as breakers and switches

-Low voltage equipment such as busbars and fuses

-Protective devices such as relays

The first thing you should check in a substation is the power source. Make sure that it is turned on and generating electricity. Next, check the high voltage equipment.

Make sure that the breakers and switches are working properly. Lastly, check the low voltage equipment. Make sure that the busbars and fuses are in good condition.

If you’re looking for a substation, there are a few things you’ll want to check. First, make sure that the substation is properly rated for the voltage and current that it will be carrying. Second, check the equipment inside the substation to ensure that it is in good working order.

Third, inspect the substation’s grounds to ensure they are adequate. Finally, take a look at the substation’s fencing and security to make sure it is up to par. By following these simple steps, you can rest assured that your substation is in good shape and ready to handle whatever comes its way.

Testing Electrical Substations

What is the Most Important Thing in a Substation?

There are many important things in a substation, but if we had to choose one, the most important thing would be the transformer. The transformer is what changes the voltage of the electricity coming into the substation, making it safe for distribution.

What is Substation Inspection?

Substation inspection is the process of assessing the condition of electrical equipment and systems in a substation. The purpose of substation inspection is to identify any potential problems that could lead to equipment failure or system interruption.

Substation inspection typically includes a visual assessment of all equipment, as well as testing of key components such as circuit breakers, transformers and busbars.

In some cases, specialized equipment may be used to assess the condition of hard-to-reach areas or inaccessible parts of the substation.

How Do You Test a Substation?

There are a few key steps to testing a substation.

The first is to check the equipment for any damage or wear and tear. This includes things like the transformer, breakers, and other electrical components.

Next, you’ll want to test the connections between all of the equipment. This includes both the high voltage and low voltage sides of the substation.

Once everything is connected and in working order, you can begin testing the actual power flow through the substation.

This will help ensure that everything is working as it should be and that there aren’t any issues with the way power is being distributed.

Finally, it’s important to monitor the substation constantly while it’s in use. This helps identify any potential problems early on so that they can be fixed before they cause major issues.

What are the Problems in Substation?

There are many problems that can occur in a substation. Some of the most common problems include:

– Equipment failures

– Human error

– Natural disasters

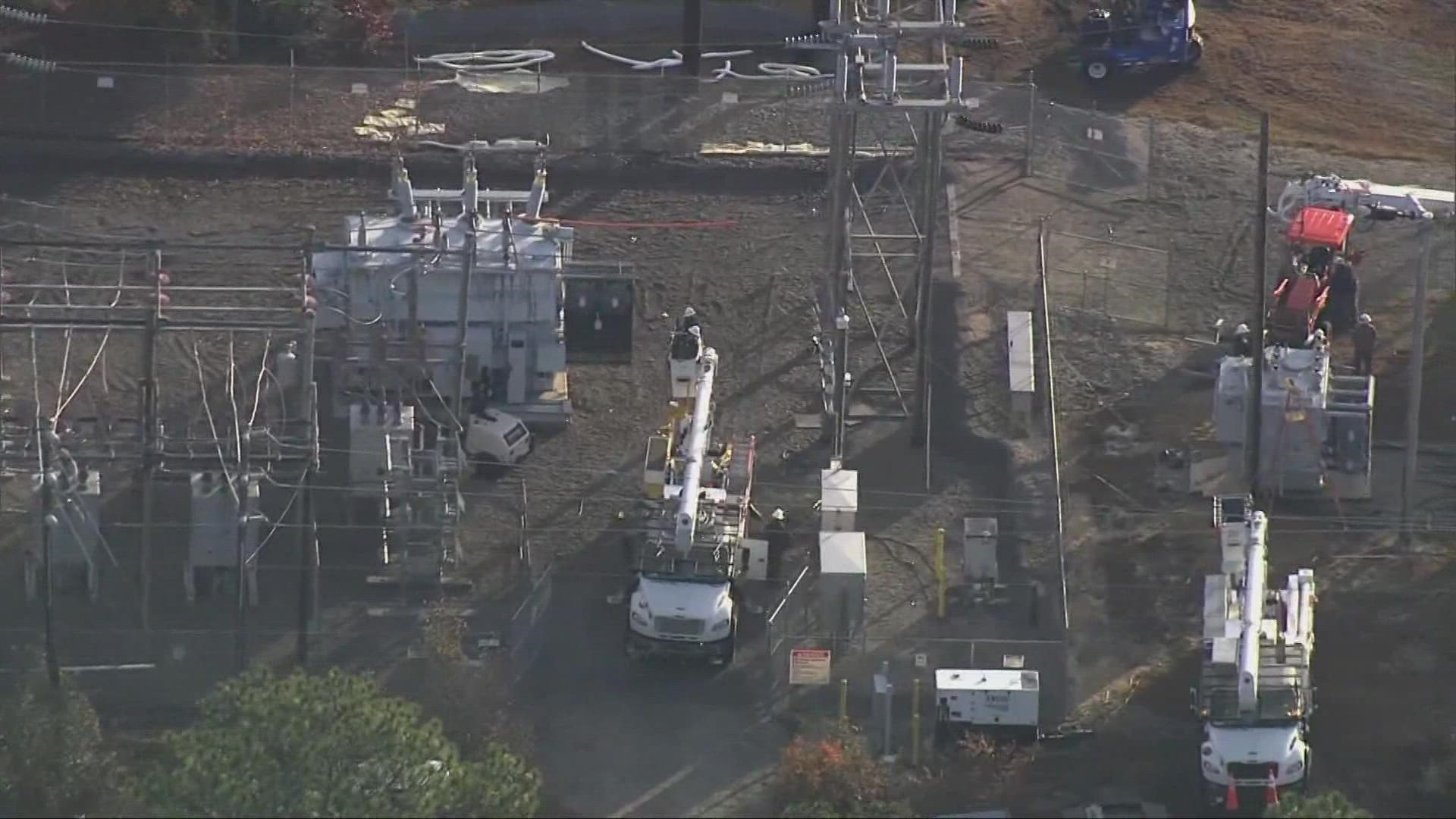

Credit: www.king5.com

Substation Checklist

If you’re responsible for maintaining a substation, it’s important to have a comprehensive checklist to ensure that everything is in working order. Here’s a detailed checklist of what should be included:

– Equipment: All substation equipment should be checked regularly, including circuit breakers, transformers, and switchgear.

Pay attention to any abnormal noises or vibrations coming from the equipment.

– Electrical connections: All electrical connections should be inspected for looseness or corrosion. Make sure that all grounding connections are secure.

– Busbars and conductors: Inspect busbars and conductors for signs of damage or excessive wear. Check that all support structures are in good condition.

– Buildings and structures: The substation buildings and structures should be checked for cracks or other damage.

The roof should be in good condition with no leaks. Also check the gutters and downspouts to make sure they’re clear of debris.

Electrical Substation Inspection Checklist Pdf

An electrical substation is a crucial link in the power grid. It regulates voltage and current, and protects equipment from overloads. A well-functioning substation is essential to keeping the power flowing.

A routine inspection of a substation can help to identify potential problems before they cause an interruption in service. This checklist provides a guide for what to look for during an inspection.

* Inspect the grounds around the substation for any trip hazards or loose debris that could fall into energized equipment.

* Check that all fence gates are securely latched and that there are no gaps in the fence line.

* Verify that all warning signs are posted and legible.

* Ensure that all access hatches are closed and locked, except for those being used during the inspection.

* Confirm that there is no unauthorized entry into any part of the substation.

* Inspect transformer oil level gauges and check for leaks around transformers, valves, and bushings.

* Look for evidence of arcing or burning on switchgear, busbars, contacts, circuit breakers, and other electrical equipment.

* Check cable terminations and splices for tightness and corrosion.

* Test relays, metering devices, alarm systems, control systems, and other electronic equipment.

* Visually inspect all electrical equipment for damage or deterioration.

By regularly inspecting a substation’s grounds, fencing, signage, entry points, transformer oil levels ,and electrical equipment ,operators can help to prevent outages caused by deteriorating conditions .

What is a Substation

A substation is an electrical facility that changes the voltage of an electric power source and distributes it to consumers. The voltage is usually increased or decreased by transformers. A substation can also be used to switch electric power sources in order to protect equipment from damage caused by sudden power surges.

Types of Substation

Substations come in a variety of shapes and sizes, each designed to meet the specific needs of the electricity grid. The three most common types of substations are:

1. Transmission Substation

A transmission substation is responsible for stepping up or down the voltage of electricity as it moves along the high-voltage transmission lines. These substations are usually large facilities that include several transformers, switchgear, and other equipment necessary to regulate voltage.

2. Distribution Substation

A distribution substation takes electricity from the high-voltage transmission lines and steps it down to a lower voltage that can be used by homes and businesses. These substations typically have one or two transformers and use less complicated switchgear than transmission substations.

3. Industrial Substation

An industrial substation is designed for use by a single factory or other large commercial facility. These substations often have multiple transformers and may step down voltage multiple times before it is sent to the customer’s equipment.

Substation Maintenance

A substation is a critical part of the electrical grid, and its maintenance is essential to ensuring a reliable supply of power. A substation typically contains high-voltage equipment, such as transformer s, that can pose a serious safety hazard if not properly maintained.

To ensure the safety of workers and the public, proper maintenance of a substation must be conducted on a regular basis.

This includes inspecting and testing equipment, as well as keeping records of all maintenance activities. In addition, it is important to have a plan in place for dealing with emergencies should they occur.

By investing in proper substation maintenance, utilities can help to ensure the reliability of their electrical grid and avoid costly disruptions.

Substation Maintenance Schedule

Substation Maintenance Schedule

A substation maintenance schedule is a plan that outlines when and how often equipment in a substation should be inspected and maintained. This schedule helps to ensure that the substation is operating safely and efficiently.

The frequency of inspections and maintenance will vary depending on the type of equipment involved. For example, circuit breakers may need to be tested monthly, while transformers may only need to be tested annually. In addition, some types of equipment may require more frequent or detailed attention than others.

Creating a substation maintenance schedule requires careful consideration of all the factors involved. But doing so can help avoid problems down the road and keep your substation running smoothly for years to come.

Substation Maintenance Procedures Pdf

As the backbone of the power grid, substations are critical to maintaining a reliable and efficient electricity supply. Given their importance, it is essential that substations are properly maintained to ensure they continue to operate as intended.

There are a number of different maintenance procedures that should be carried out on substations on a regular basis.

These include:

Inspection: A visual inspection of the substation should be conducted regularly to check for any signs of damage or deterioration. This can help identify any potential problems so they can be rectified before they cause major issues.

Cleaning: The substation and surrounding area should be kept clean and free from debris to prevent any potential hazards. This includes removing vegetation that could grow into and damage equipment.

Testing: Electrical equipment within the substation needs to be regularly tested to ensure it is still functioning correctly.

This testing can be done using specialist equipment or by carrying out simulated failures under controlled conditions.

Repair and replacement: If any damage is found during an inspection or test, repairs will need to be carried out as soon as possible. In some cases, it may be necessary to replace damaged equipment entirely.

Conclusion

If you’re looking for a substation, there are a few things you should check. First, make sure the substation is properly grounded. This is important for safety and for preventing damage to equipment.

Second, check the voltage and amperage of the substation. This will ensure that it can handle the load you need it to. Finally, inspect the condition of the equipment.

If it looks old or damaged, it may not be able to handle your needs.