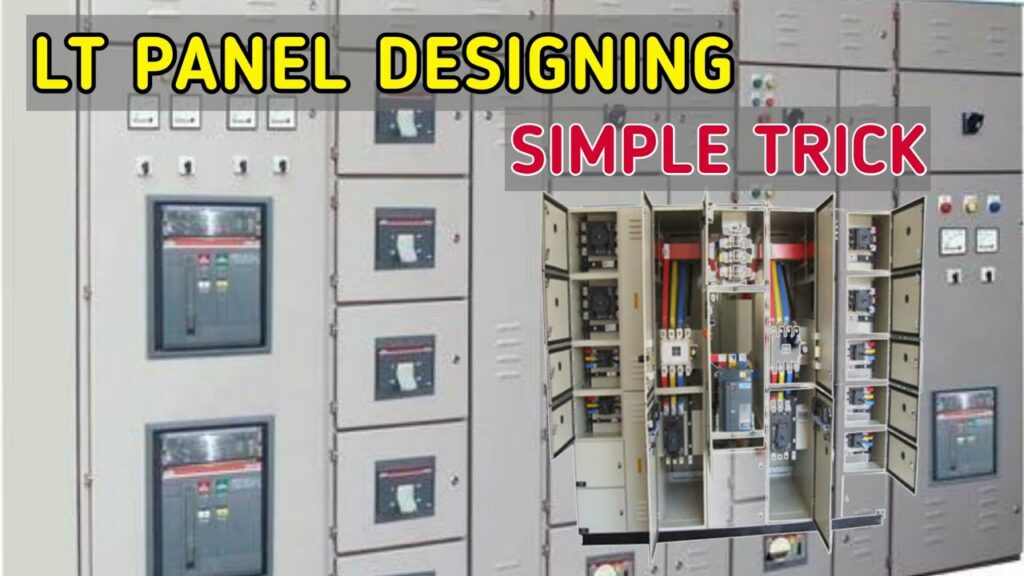

A substation lt panel is a key component in the electrical distribution system. It allows for the safe and reliable transfer of power from the utility to the customer. The substation lt panel must be designed to meet the specific needs of the application and meet all relevant safety standards.

Switchgear Main LT Distribution Panel Making and Wiring step by step | Electrical panels

- Select the proper transformer for the application

- Select the proper breaker for the application

- Coordinate the transformer and breaker so that they are compatible with each other and can be used in the same substation panel

- Choose the right size of bus bar to connect the transformer and breaker together in the substation panel

- Make sure all cables, wires, and other components are properly sized and rated for use in the substation panel

Substation Design Pdf

When it comes to substation design, there are a few things you need to take into account. First and foremost amongst these is the fact that substations come in a variety of shapes and sizes, so you will need to make sure that your design takes this into account. You also need to consider the voltage and current requirements of the substation, as well as the environmental conditions surrounding it.

All of these factors will play a role in determining the overall design of your substation.

One of the most important aspects of substation design is safety. This is why it is so important to work with an experienced professional who can help you ensure that your substation meets all relevant safety standards.

In addition to this, you also need to think about security when designing your substation. This means making sure that only authorized personnel have access to the facility, and that any potential hazards are properly mitigated.

Another key consideration for substation design is efficiency.

Your goal should be to create a facility that can meet the demands of your specific application while minimizing energy consumption. This can be achieved through careful planning and execution, so again, working with an experienced professional is essential.

Finally, you also need to think about maintenance when designing your substation.

Even the best-designed facilities require regular maintenance in order to stay operational, so make sure that your plans include provisions for this eventuality. By taking all of these factors into account, you can be sure that your substation design will be successful both now and in the future.

Electrical Substation Design Calculations Pdf

As the demand for electricity increases, so does the need for larger, more efficient electrical substations. The design of an electrical substation must take into account many factors, including the amount of power to be transmitted, the voltage level, the environmental conditions, and the space available.

To ensure that an electrical substation can handle the load it is meant to support, engineers use a variety of design calculations.

These calculations take into account such factors as thermal rating of equipment, short-circuit current levels, and coordination of protection devices. By performing these calculations early on in the design process, engineers can avoid problems later on and ensure that the substation will operate safely and efficiently.

Substation Construction Guidelines Pdf

If you’re in the process of constructing a substation, there are a few important guidelines to keep in mind. First and foremost, all substation construction must be performed in accordance with industry best practices and local, state, and federal regulations. Additionally, it’s important to have a clear understanding of the project scope before beginning work.

This includes knowing the desired capacity of the substation, the type of equipment that will be installed, and any other relevant details.

Once you have a good grasp on the project scope, it’s time to start thinking about the actual construction process. There are a few different approaches that can be taken when constructing a substation, but one of the most important things to keep in mind is safety.

All workers should be properly trained and equipped with personal protective gear (PPE) before beginning work.

When it comes to actually building the substation, there are a few key components that must be considered. The first is the foundation; this needs to be strong enough to support the weight of the equipment that will be installed.

Next is the electrical system; this must be properly designed and installed according to code in order to ensure safe operation of the substation. Finally, various pieces of equipment need to be carefully selected and installed; this includes everything from switchgear to transformers.

By following these guidelines during construction, you can help ensure that your substation is safe and efficient.

Substation Design Standards

Substation design standards are important for the safe and reliable operation of electrical substations. These standards cover the design, construction, testing, commissioning, and maintenance of substations. They ensure that substations are designed and built to meet the specific needs of their intended purpose and operating environment.

The most common substation design standards are published by IEEE and IEC. IEEE Standards Association (IEEE-SA) develops safety standards for the electrical power industry worldwide. The International Electrotechnical Commission (IEC) is a leading global organization that prepare international standards for all electrical, electronic and related technologies.

Both IEEE and IEC have established committees to develop substation design standards. In the US, IEEE’s Committee on Substations (C1) is responsible for developing these standards. IEC’s Subcommittee on Electrical Installations of Buildings (TC79) also develops international substation design standards.

The most commonly used IEEE standard for substation design is IEEE Std 693-2016, “Standard Requirements for Substation Equipment”. This standard covers the requirements for equipment used in electric power transmission and distribution substations at voltages exceeding 1000 V up to but not including 230 kV rms phase-to-phase voltage or 345 kV dc voltage between conductors [1]. It includes requirements for equipment enclosures; supports; switchgear assemblies; buswork arrangements; cabling systems; cable terminations; grounding systems; control systems; metering devices; monitoring devices; protection devices; transformers; capacitors banks/reactors/filters/smoothing reactors/neutral current limiters/etc.

; surge arresters/lightning arrestor sets (LAS); shunt capacitor sets (SCS); voltage regulators (VRs); rotary converters(RCs), static var compensators(SVCs), etc.; generators interfacing with utility grid via power electronic converters(PECs); battery plants & chargers(BP&Cs). Other important considerations addressed by this standard include environmental conditions, such as temperature extremes, humidity levels, altitude, salt air exposure ,ice storms ,tornados ,hail storms ,windstorms hurricanes earthquakes floods lightning strikes solar flares electromagnetic pulses(EMP).

Additional guidance on meeting these requirements can be found in various application notes published by vendors of electrical equipment [2][3][4][5].

References:

Ht & Lt Panel Basics Pdf

An Ht & Lt Panel is a basic electrical panel that is used to distribute power in a home or office. It is typically mounted on the wall and has two main circuits, one for high voltage and one for low voltage. The panel also has a number of other circuits that are used for specific purposes, such as lighting or appliances.

Credit: instrumentationtools.com

How to Design a Substation?

Designing a substation involves understanding the electrical system loads, selecting equipment and determining the layout to meet safety and reliability requirements.

Substations come in all shapes and sizes, from small rural operations to large urban facilities. The first step in substation design is to understand the customer’s needs.

What are their load demands? How often do they need service? What are their expansion plans?

Once these questions have been answered, the engineer can begin to select the proper equipment and determine an efficient layout.

There are many different types of equipment that can be used in a substation, including breakers, transformers, capacitors, inductors, surge arrestors and more. Each type of equipment has its own set of characteristics that must be considered when making a selection.

For example, breakers come in various sizes and speeds; some are designed for low-voltage applications while others can handle very high voltages. Selecting the right breaker for the job is critical to ensuring safe and reliable operation of the substation.

Once the proper equipment has been selected, it must be properly installed according to manufacturer’s instructions and local codes.

This includes ensuring that all connections are tight and secure, wiring is correctly sized and routed away from potential sources of damage or interference, and that all devices are properly grounded.

After installation is complete, testing should be done to verify that everything is functioning as it should. This might include running simulated load tests or measuring voltage levels under various conditions.

Once everything has been verified, the substation will be ready for operation!

What are the Components of Lt Panel?

An LT panel, or low-transmission panel, is a type of optical filter that is used to reduce the amount of light that passes through it. The most common type of LT panel is made from a material called polyethylene terephthalate (PET), which has a very low level of light transmission. Other materials used for LT panels include polycarbonate (PC) and glass.

LT panels are used in a variety of applications where it is important to reduce the amount of light that passes through, such as in LCD screens and solar cells. They can also be used to block out unwanted light, such as in eyeglasses and camera filters.

What Should I Consider in Substation Design?

When it comes to substation design, there are a few key considerations that need to be taken into account. First and foremost amongst these is the question of safety. A substation needs to be designed in such a way that it minimises the risk of harm to both workers and the public.

This means ensuring that all electrical equipment is properly insulated and enclosed, and that there are adequate barriers between areas of high voltage and low voltage.

Another key consideration in substation design is efficiency. The layout of a substation needs to be planned in such a way as to minimise power losses through resistance.

This includes paying careful attention to the routing of electrical cables, and using materials with low resistivity wherever possible. In addition, the use of advanced control systems can help to further reduce power losses by optimising operating conditions within the substation.

Finally, it is also important to consider the future expansion potential of a substation when designing it.

This means planning for additional capacity beyond what is required for present-day needs, so that the substation can accommodate future growth without needing to be completely rebuilt. By taking all of these factors into account, it is possible to design an effective and efficient substation that will meet the needs of both present and future generations.

What is an Lt Panel?

An LT panel is a laminated transformer panel that houses the windings of a transformer. The LT panel is designed to be used in environments where there is a need for high levels of electrical insulation. The panels are made from a variety of materials, including glass-reinforced epoxy and polyester.

Conclusion

Substation lt panel are an important part of the electrical grid. They help to regulate the flow of electricity and keep the power flowing to homes and businesses. Here are some tips on how to design a substation lt panel:

– Work with an experienced engineer who can help you understand the local regulations and requirements for your project.

– Consider the size of your substation and the amount of power that will be flowing through it. This will determine the number of breakers and other components that you’ll need.

– Make sure that your substation is easily accessible for maintenance and repairs. This means placing it in a location that is convenient for workers to get to.

– Design your substation with safety in mind.

This includes using materials that won’t conduct electricity, such as fiberglass or PVC, and making sure there are no sharp edges where someone could get hurt.