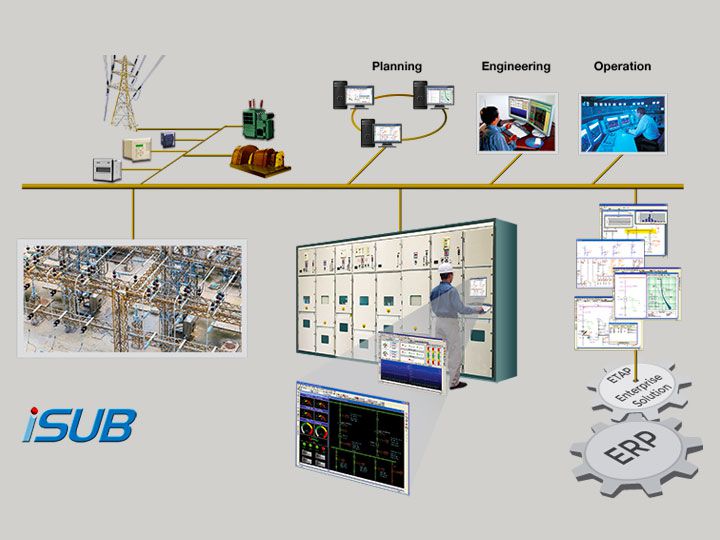

A SCADA system is used in a substation to remotely monitor and control the electrical equipment. The system typically includes sensors, controllers, and communication devices that are connected to the electrical equipment. The data from the sensors is used to monitor the equipment and make decisions about how to operate it.

The controllers can be used to remotely turn equipment on or off, change settings, or take other actions.

HOW TO WORK SCADA, SCADA SYSTEM, 132/33 SUBSTATION, NEW SCADA SYSTEM

Scada systems play a vital role in the safe and reliable operation of electrical substations. They are used to monitor and control equipment, such as transformers, circuit breakers, and switchgear. Scada systems can also be used to remotely operate equipment and provide status information to operators.

Scada System for Substation Pdf

Substation automation is the process of using SCADA to remotely monitor and control equipment at substations. Substation automation systems can be used to monitor and control a variety of electrical equipment, including:

-Transformers

-Circuit breakers

-Capacitors

-Switches

In addition to monitoring and controlling this equipment, substation automation systems can also be used to collect data from various devices within the substation. This data can be used to generate reports that help engineers troubleshoot problems and improve the overall efficiency of the substation.

Scada in Power System Ppt

Scada systems are used extensively in power system applications. They provide a means of monitoring and controlling equipment and processes remotely. Scada systems typically consist of a central computer, which is connected to a network of remote devices via communication links.

The remote devices may be located at different sites, or they may be integrated into the same equipment. The communication links can be either wired or wireless.

The main advantage of using Scada systems in power system applications is that they allow for the centralized control of multiple devices and processes.

This can lead to more efficient operation of the overall system, as well as increased safety and reliability. In addition, Scada systems can provide real-time data about the status of the equipment and processes they are monitoring. This information can be used to make decisions about how to operate the system more effectively.

There are many different types of Scada systems available on the market today. Some are designed specifically for use in power applications, while others are more general purpose. When choosing a Scada system for use in a power system application, it is important to select one that is compatible with the specific equipment and process being monitored and controlled.

In addition, it is important to ensure that the system has adequate security features to protect against unauthorized access and tampering.

Scada in Power System Pdf

The term SCADA stands for Supervisory Control and Data Acquisition. A SCADA system is used to monitor and control a variety of devices and systems within an industrial environment. The system can be used to monitor everything from the temperature of a factory floor to the output of a power plant.

A SCADA system typically consists of four main components: sensors, controllers, communication infrastructure, and HMI (human machine interface). Sensors are used to collect data from the various devices and systems being monitored by the SCADA system. This data is then sent to controllers, which use algorithms to process the data and make decisions about how to control the devices or systems.

The communication infrastructure is used to relay information between the sensors, controllers, and HMI. Finally, the HMI is used by operators to interact with the SCADA system in order to monitor conditions and make changes as needed.

One of the great advantages of using a SCADA system is that it can be customized to meet the specific needs of any given industrial environment.

Additionally,SCADA systems are highly scalable; they can be designed to accommodate a few dozen devices or several thousand devices depending on need.

Scada System Pdf

When it comes to industrial automation, Scada systems are an essential part of many operations. A Scada system is used to collect data from various sources and then present that information in a way that is easy for humans to understand. In many cases, Scada systems are used to control processes and machinery remotely.

One of the most important aspects of a Scada system is its ability to gather data from multiple sources simultaneously. This data can come from sensors, input devices, output devices, or even manual input from operators. Once this data has been collected, it can be processed and displayed in various ways depending on the needs of the user.

Substation Automation System Abb

Substation automation systems are critical for the safe, efficient and reliable operation of power networks. They provide high levels of protection, monitoring and control functionality, while also enabling the integration of renewable energy sources into the grid.

ABB is a global leader in substation automation, with over 30 years of experience in delivering systems for a wide range of applications.

Our solutions are based on open standards and offer seamless interoperability with other devices and systems in the network. This allows utilities to implement flexible and cost-effective solutions that meet their specific needs.

ABB’s substation automation products and solutions include:

– Intelligent Electronic Devices (IEDs)

– Substation Control Systems (SCADA)

– Energy Management Systems (EMS)

– Distributed Energy Resource Management Systems (DERMS)

Substation Automation System Tutorial

Substation automation system is a computerized system that monitors and controls the electrical equipment and process in substations. It automates the monitoring, data collection, analysis, reporting, and decision-making process to improve the reliability of power supply.

A substation typically contains high voltage equipment such as switchgear, transformers, capacitors, reactors, circuit breakers etc. which are required for generation, transmission and distribution of electricity.

A typical substation can have 10 to 10000 HV/MV feeders connected to it. The growing electrification rate and rapid industrialization has led to an exponential growth in the number of substations around the world.

Application of Scada in Power System

Application of Scada in Power System

The use of SCADA systems in power system has greatly increased in the past few years. This is because SCADA systems offer many benefits to utilities, including improved system performance, reduced operating costs, and improved safety.

Let’s take a closer look at how SCADA systems are used in power system applications.

One common application of SCADA systems is for monitoring and controlling the electric grid. For example, a utility may use a SCADA system to monitor voltage levels and current flow throughout the grid.

This information can be used to improve grid stability and prevent blackouts. In addition, by monitoring the grid closely, utilities can identify potential problems before they cause disruptions.

Another common application of SCADA systems is for managing distributed energy resources (DERs).

DERs include solar panels, wind turbines, and other renewable energy sources that are connected to the electric grid. As more DERs are installed across the country, it becomes increasingly important to have a way to manage them effectively. That’s where SCADA systems come in.

By using a SCADA system, utilities can remotely monitor and control DERs to ensure they are operating safely and efficiently. Additionally,SCADA data can be used to optimize DER operations and help integration into the grid.

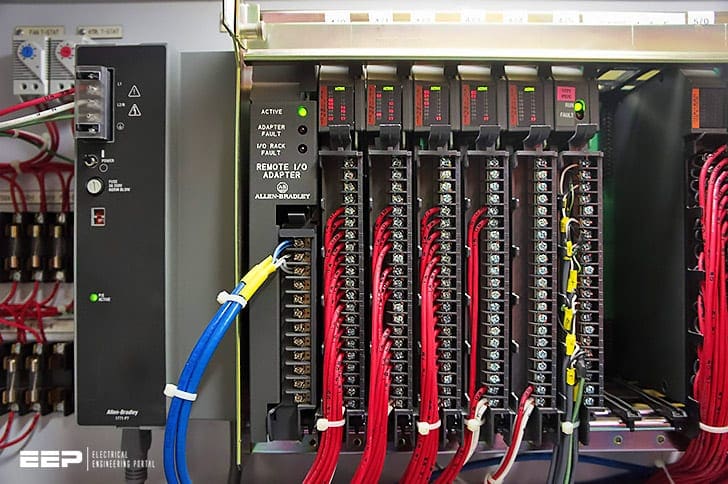

Credit: electrical-engineering-portal.com

What is the Importance of Scada in Substation?

SCADA systems are important in substations because they allow for the remote monitoring and control of equipment. This can help to improve efficiency and reduce downtime by allowing operators to quickly identify and address problems. Additionally, SCADA data can be used to trend equipment performance over time, which can help with predictive maintenance planning.

What is Scada in Electrical System?

SCADA stands for Supervisory Control and Data Acquisition. It is a type of industrial control system that monitors and controls industrial processes and infrastructure. SCADA systems are used in a variety of industries, including water and wastewater, oil and gas, electric power, transportation, and manufacturing.

A SCADA system typically consists of four main components: sensors and actuators, controllers, Human-Machine Interfaces (HMIs), and communication infrastructure. Sensors and actuators are devices that measure or change physical quantities such as temperature, pressure, flow rate, etc. They are connected to the controller which is responsible for monitoring and controlling the process based on setpoints or algorithms.

The HMI provides a graphical interface for operators to interact with the controller in order to monitor process variables and make changes if necessary. The communication infrastructure allows data to be exchanged between the various components of the system (e.g., between the controller and HMI).

SCADA systems can be used to monitor & control just about any type of process or equipment imaginable.

In fact, they’re even being used more frequently in non-industrial applications such as building automation & security systems.

What are the Three 3 Types of Scada?

There are three types of SCADA systems: centralized, distributed, and web-based. Centralized SCADA systems have a single server that collects data from all the devices in the system. Distributed SCADA systems have multiple servers that collect data from devices in different locations.

Web-based SCADA systems use a web browser to access data from devices in the system.

What are the Types of Functions Performed by Scada in Substation Control?

There are many types of functions that can be performed by a SCADA system in substation control. These include monitoring and controlling the voltage and current flowing through the substation equipment, as well as the temperature and pressure of various devices. Additionally, SCADA systems can be used to monitor and record data from various sensors located throughout the substation, providing valuable information for operators.

Conclusion

Substations are an important part of the electrical grid. They help to control the flow of electricity and protect equipment from damage. A Scada system can be used in a substation to help monitor and control the equipment.

This can help to improve the efficiency of the substation and prevent problems from occurring.