Load calculation is the process of determining the amount of electric power required by an electrical system. The load can be either AC or DC. The load can also be single-phase or three-phase.

Load calculation must take into account the type of loads, such as motors, lighting, and computers. It must also consider the power factor of the loads.

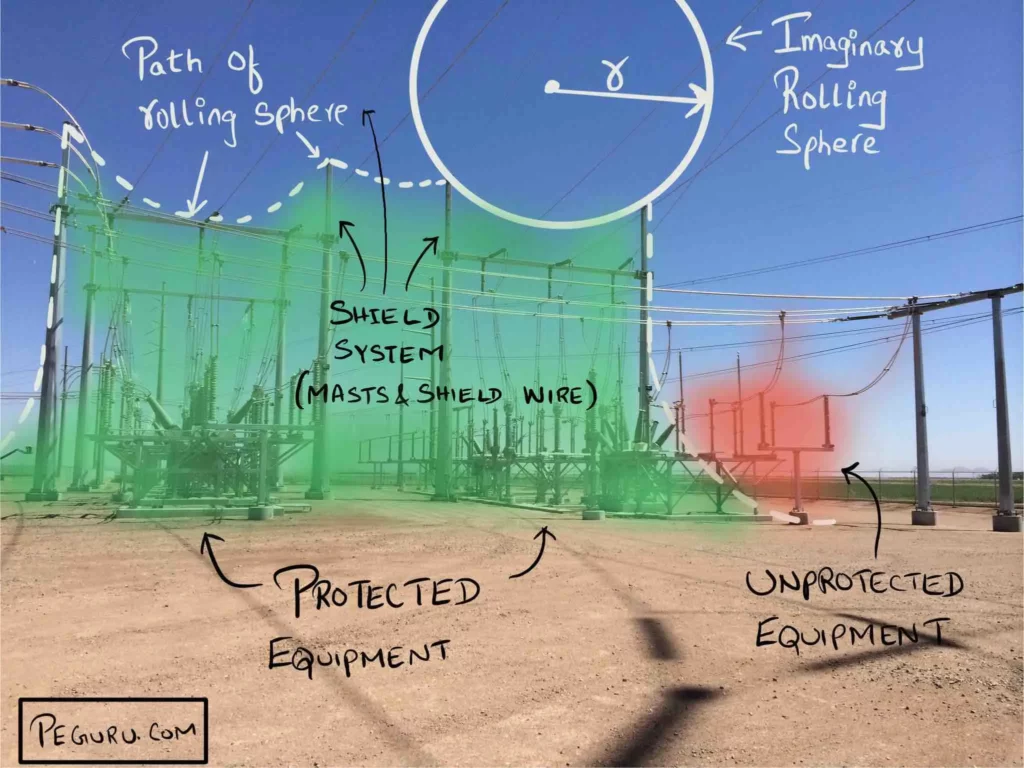

A substation is an integral part of the electrical grid. Its primary purpose is to take the high-voltage electricity from the transmission lines and step it down to a lower voltage so that it can be used by consumers. A substation also has other functions, such as providing power to local utilities, monitoring and controlling the flow of electricity, and protecting equipment from voltage spikes.

The load calculation for a substation is a critical part of its design. The load must be carefully calculated in order to ensure that the substation can meet the demands placed on it by the electrical grid. The load calculation takes into account factors such as the number of transformers, the type of loads connected to each transformer, and the anticipated demand for electricity.

Electrical Substation Design Calculations Pdf

An electrical substation is a vital link in the power system. It is responsible for receiving electricity from the generating station and then transmitting it to the distribution system. The substation also plays an important role in providing protection to the equipment and personnel working on site.

To ensure that a substation is designed and built correctly, various calculations must be carried out. These calculations take into account factors such as the voltage of the incoming electricity, the amount of current that will be passing through the substation, and the environmental conditions at the site.

Once these calculations are complete, the substation can be designed to meet all safety requirements and operate efficiently.

Substation Design Calculations Excel

As an electrical engineer, you may be tasked with the design of a substation. This can be a daunting task, as there are many factors to consider and calculations to perform. However, using Excel can help streamline the process and make it more efficient.

Let’s take a look at some of the key considerations and calculations involved in substation design.

First, you’ll need to determine the voltage level of the substation. This will dictate the size and type of equipment required.

Next, you’ll need to calculate the power demand of the substation. This will help you determine the number of transformers and other components needed. Additionally, you’ll need to consider things like short-circuit current levels, conductor sizes, and insulation levels.

All of these factors must be considered in order to properly design a substation that meets all safety requirements.

Excel can be a helpful tool in performing all of these calculations quickly and accurately. There are many different formulas that can be used for each calculation, so it’s important to know which ones to use for your particular project.

Additionally, there are many different templates available online that can further streamline the process by providing pre-built worksheets for specific types of substations. By leveraging Excel in your substation design projects, you can save time and ensure accuracy in your designs.

Electrical Substation Design Pdf

An electrical substation is a crucial part of the electricity grid. It is where high-voltage transmission lines meet lower-voltage distribution lines, and it plays an important role in regulating voltage and managing power flow.

There are many factors to consider when designing an electrical substation, including safety, reliability, efficiency, and cost.

The layout of a substation must be carefully planned to accommodate all of the equipment and ensure safe and reliable operation.

Safety is the primary concern in any substation design. All equipment must be properly rated for the voltages present, and all switchgear must be enclosed to prevent accidental contact with live parts.

There must also be adequate clearance around all electrical equipment to prevent fire hazards.

Reliability is also important in substation design. All equipment must be designed to operate safely under normal conditions as well as under extreme conditions such as severe weather or system faults.

redundant systems and components can help improve reliability by providing backup options if one system fails.

Efficiency is another key consideration in substation design. Equipment that is well-maintained and operated correctly will use less energy and require less maintenance than poorly designed or maintained equipment.

This can lead to lower operating costs over time.

Substation Grading

A substation is a critical part of the electric power grid. It is a junction point where high-voltage transmission lines meet and connect to lower-voltage distribution lines. Substations are also where voltage is transformed from one level to another.

All of this makes proper grading around a substation essential.

There are several factors to consider when grading around a substation. First, the grade must be designed to shed water away from the substation equipment.

This helps prevent flooding and keeps the equipment dry and operational. Second, the grade should allow for easy access to the substation for maintenance and repairs. Third, the grade should provide adequate drainage so that water does not pond around the substation equipment.

Proper grading around a substation is essential to its safe and reliable operation. By following these guidelines, you can help ensure that your substation continues to provide power to your community for years to come.

How to Calculate Transformer Load Capacity

A transformer load is the total amount of power that a transformer can handle. The capacity of a transformer is often expressed in kVA or MVA. To calculate the load capacity of a transformer, you need to know the voltage and current ratings of the transformer.

The following formula can be used to calculate the load capacity of a transformer:

Load Capacity (kVA) = Voltage (V) x Current (I) / 1,000

For example, if you have a transformer with a voltage rating of 240 V and a current rating of 30 A, the load capacity would be:

Substation Design Standards

In the United States, substation design standards are governed by the National Electrical Safety Code (NESC). The NESC is a set of standards developed and maintained by the Institute of Electrical and Electronics Engineers (IEEE) that provides guidelines for the safe operation and maintenance of electrical equipment.

Substation design standards are important to ensure the safety of both workers and the general public.

A well-designed substation will minimize the risk of electrical hazards and provide a safe environment for both workers and the public.

There are several key components to consider when designing a substation, including:

-Location: The location of a substation should be selected based on several factors, including proximity to load centers, existing infrastructure, topography, soil conditions, and climate.

-Accessibility: Substations must be designed with adequate access for maintenance personnel.

-Security: Substations should be designed with security in mind to protect against unauthorized entry or vandalism.

-Safety: All substation components should be designed with safety in mind.

This includes using proper materials and engineering controls to mitigate risks associated with arc flash hazards, fire hazards, and electrocution hazards.

Specification for Electrical Load Calculation

The NEC (National Electrical Code) has a section that provides detailed information about electrical load calculation. This section is titled “Specification for Electrical Load Calculation” and can be found in Chapter 9 of the NEC. This specification covers the requirements for calculating the maximum demand loads for feeders and branch circuits serving residential, commercial, and industrial occupancies.

The purpose of this specification is to provide a consistent method for determining the maximum demand loads on feeders and branch circuits. This will ensure that the circuit capacity is not exceeded and that safety is not compromised.

There are three methods specified in this section for calculating maximum demand loads: the whole house method, the optional method A, and optional method B. Method A is used to calculate the total load on a circuit by using values from Tables 220.3(A)(1) through (A)(14).

These tables give demands factors based on occupancy type and number of stories served by the circuit. Method B can be used to calculate either the total or partial load on a circuit by using values from Tables 220.54(B)(1) through (B)(4). These tables give percentage multipliers based on building type, number of occupants, equipment group, air-conditioning status (on or off), seasonality factor, etc.

The whole house method simply uses an assumed value of 100% for each parameter listed in Tables 220.3(A)(1) through (A)(14). While this may not always accurately represent reality, it will provide a worst-case scenario which ensures safety while still providing adequate power to meet peak demands.

Once you have determined which method you will use to calculate your maximum demand loads, you must then determine what your unit loads are going to be.

Unit loads are defined as “the maximum average watts per square foot of floor area or equivalent dwelling unit served by any one appliance or piece of equipment” (NEC 9th Edition 2014 pgs 8-9). When making your calculations, you must consider all appliances and pieces of equipment that could possibly be running at one time during peak demand periods. Some examples of these items would be air conditioners, water heaters, ranges/ovens, clothes dryers, dishwashers etc..

Credit: blog.copadata.com

How Do You Calculate Substation Load?

A substation load is the maximum amount of power that can be safely delivered to a substation by the utility company. The safe delivery of power is dependent on many factors, including transformer capacity, conductor size and insulation type. Most utility companies have standard formulas for calculating substation loads.

These formulas take into account the voltage and amperage ratings of the transformers and conductors at the substation.

How Do You Calculate Load Value?

There are a few different ways that you can calculate load value, depending on what information you have available. One way to calculate load value is by using the following formula:

Load Value = (Weight of Item / Capacity of Truck) x 100

So, for example, if you have a truck with a capacity of 10,000 lbs and you’re carrying a load of 5,000 lbs, your load value would be 50%. Another way to calculate load value is by using the following formula:

Load Value = (Volume of Item / Capacity of Truck) x 100%

For example, if your truck has a capacity of 1,000 cubic feet and you’re carrying 500 cubic feet worth of goods, your load value would be 50%. A final way to calculate load value is by using the following formula:

Load Value = (Number of Items / Capacity of Truck) x 100%

Using this method, if your truck has a capacity for 20 items and you’re carrying 10 items, your load value would be 50%. As you can see, there are several different ways that you can calculate load value – it just depends on what information you have available.

How Much Power Can a Substation Handle?

A substation is a critical part of the electrical grid, and its capacity to handle power is crucial to keeping the lights on. But how much power can a substation actually handle?

The answer depends on a number of factors, including the type of equipment at the substation, the voltage of the electricity being transmitted, and the amount of cooling available.

Generally speaking, however, most substations are designed to handle between 60 and 200 megavolt-amperes (MVA) of power.

Some substations are even capable of handling much more than that. The largest substation in North America, for example, is capable of handling up to 1200 MVA.

That’s enough power to keep millions of homes and businesses running even if everything else on the grid goes offline.

In other words, when it comes to keeping the lights on, we can all rest a little bit easier knowing that our local substations have got us covered – no matter how big or small they may be.

How Do You Calculate Transformer Load?

It is quite easy to calculate the load on a transformer. The first step is to find the power rating of the device. This can be found on the nameplate, which is usually located on the side or bottom of the unit.

Once you have this number, simply multiply it by the number of devices that will be used with it. For example, if you have a 100 watt transformer and you are using two 100 watt light bulbs, your total load would be 200 watts.

Substation Design, Capacity Calculation & Selection – সাব-স্টেশন ক্যালকুলেশন

Conclusion

The purpose of this blog post is to provide an overview of load calculation for substations. Substation load calculation is the first step in determining the size and type of equipment needed for a new or upgraded substation. The load calculation must take into account the maximum demand, future growth, voltage levels, short-circuit currents, and other factors.

An accurate load calculation is essential to ensuring that the substation can meet the future needs of the electric system.