The Fault Level of a substation is the maximum short circuit current that can flow through the substation without causing damage to the equipment. The Fault Level is determined by the amount of short circuit current that the equipment can safely handle.

Fault Level Calculation in Power System | Power System Operation | Fault Level Calculation

In electrical engineering, the fault level of a substation is the maximum short-circuit current that can flow through the substation’s equipment. The fault level is an important factor in the design of electrical power systems, as it determines the amount of electrical energy that can be safely handled by the system.

The fault level of a substation is typically determined by its location in the power system.

Substations located near sources of high short-circuit currents, such as generators and large transformers, have higher fault levels than those located further away from these sources. The highest fault levels are typically found at generating stations and large transformer plants.

The amount of short-circuit current that flows through a substation’s equipment during a fault depends on several factors, including the type of equipment used, the operating conditions at the time of the fault, and the impedance of the circuit between the source of short-circuit current and the substation.

Fault Level Calculation of Substation

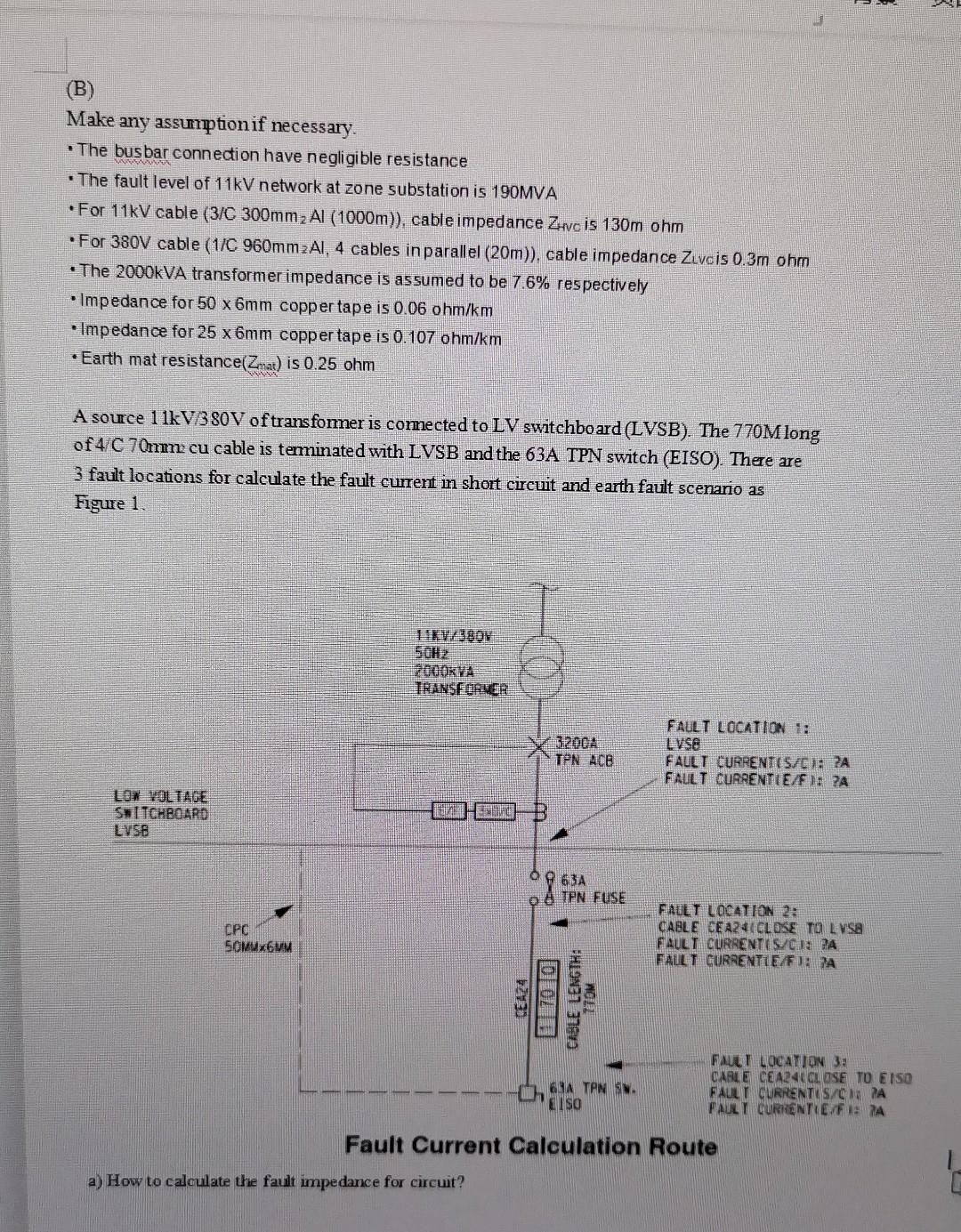

When calculating the fault level of a substation, there are a few key pieces of information that must be taken into account. The first is the voltage of the system. This will dictate the amount of current that can flow through the system in the event of a short circuit.

The second is the impedance of the system. This will help to determine how much power is dissipated as heat during a short circuit and will also help to limit the amount of current that can flow through the system. Finally, the length of conductor run must be considered.

This will impact both the voltage drop across the conductor and alsothe maximum amount of current that can flow through it before damage occurs. All of these factors must be considered when designing or selecting a substation transformer for use in your facility.

Fault Level at 11Kv System

What is Fault Level?

Fault level is the maximum amount of electrical current that can flow through a given point in a power system before the system fails. The term is typically used to refer to the maximum short-circuit current that can flow through a particular component or section of a power system.

How is Fault Level Measured?

Fault level is typically measured in terms of amperes (amps). The actual measurement of fault level depends on the type of equipment being used and the specific circumstances under which the measurement is being taken.

For example, when testing circuit breakers, manufacturers will use different methods to determine the breaker’s maxi mum interrupting rating (MIR), which is a measure of the breaker’s ability to safely handle high levels of electrical current.

However, regardless of how it is measured, fault level always refers to the maximum amount of current that can flow through a given point in a power system without causing damage to the system or posing a safety hazard.

Why Is Fault Level Important?

Fault level is important because it provides information about how much electrical current a power system can safely handle. This information helps engineers design systems that are safe and reliable, and it helps utility companies maintain their systems so that they can continue providing service to customers without interruption.

Additionally, knowing the fault levels for various components in a power network can help troubleshooters identify problems more quickly and efficiently.

For example, if there is an unexpected drop in voltage at one location in a network, investigators will likely check for faults upstream from that location until they find the component with the highest fault level. By doing this, they can isolate wherethe problem originated and take steps to fix it as quickly as possible.

Fault Level Calculation Pdf

Fault level calculation is a process of determining the maximum amount of current that can flow through a particular electrical circuit without causing damage to the equipment or system. It is important to know the fault level of your electrical system in order to avoid overloading it and causing a fire or other disaster.

There are three different ways to calculate fault level:

1) by using Ohm’s Law,

2) by using the National Electrical Code (NEC), or

3) by using a software program designed for this purpose.

Let’s take a closer look at each method:

Ohm’s Law Fault Level Calculation: This method is based on the simple formula I=V/R, where I is current in amps, V is voltage in volts, and R is resistance in ohms. To use this method, you need to know the voltage of your system (typically 120 or 240 volts), as well as the total resistance of all conductors and devices in the circuit.

Once you have these values, simply plug them into the formula and solve for I. This will give you the maximum amount of current that can flow through your system before damage occurs.

For example, let’s say you have a 120-volt circuit with 100 feet of 14-gauge copper wire (the most common type of residential wiring). The total resistance of this circuit would be 0.4 ohms ((100 ft x 0.006 ohms/ft)/(14 gauge)).

Plugging these values into our equation we get: I = 120 volts / 0.4 ohms = 300 amps. So according to Ohm’s Law, this circuit can handle up to 300 amps of current before damage occurs.

However, there are some limitations to using Ohm’s Law for fault level calculation.

First, it only applies to direct current (DC) systems; alternating current (AC) systems are more complicated and require a different approach entirely. Second, it only applies when all devices in the circuit are operating at their rated values; if any devices are operating above or below their ratings then additional factors must be considered which makes things even more complicated. Finally, even if all these conditions are met perfectly there is still margin for error because real-world resistances are never exactly equal to their theoretical value due largely to conductor skin effect and proximity effect .

Fault Level Calculation Excel

Fault level calculation is the process of determining the maximum amount of electrical current that a conductor can carry without sustaining damage. This value is important in the design and construction of electrical power systems, as it determines the size and type of conductor required to safely carry the desired amount of current.

There are a number of different methods that can be used to calculate fault level, but the most common is the RMS (root mean square) method.

This approach uses a mathematical formula to determine the maximum possible value of AC current that a conductor can carry without sustaining damage.

The RMS method is generally considered to be more accurate than other methods, such as the peak or average values, because it takes into account both the positive and negative peaks of AC current flow. It is important to note, however, that this method only provides an estimate of maximum current carrying capacity and does not guarantee that no damage will occur at lower levels.

Once the maximum fault level has been determined, it is then necessary to select a conductor that is capable of carrying this amount of current without sustaining damage. The American Society for Testing and Materials (ASTM) has established standards for a variety of different types of conductors, which can be used to select an appropriate option for your application.

Fault Level Calculation Ppt

Fault level calculation is the process of determining the maximum amount of voltage or current that can flow through a given electrical system without causing damage to the system. This information is used to design and operate electrical systems safely.

There are two main types of fault level calculation: steady-state and transient.

Steady-state fault level calculation determines the maximum amount of voltage or current that can flow through an electrical system under normal operating conditions. Transient fault level calculation determines the maximum amount of voltage or current that can flow through an electrical system during a short period of time, such as during a power outage or equipment failure.

Both steady-state and transient fault level calculations are important for safe operation of electrical systems.

For example, if an electrical system is designed for a certain steady-state voltage but experiences a higher transient voltage during a power outage, the system may be damaged by the higher voltage. Similarly, if an electrical system is designed for a certain transient current but experiences a higher steady-state current under normal conditions, the system may overheat and fail.

Fault level calculation is typically performed using computer software that models the behavior of electricity in complex systems.

This software allows engineers to input data about an electrical system and then simulate different scenarios to determine what might happen under various conditions.

Computer modeling isn’t perfect, however, and there’s always some uncertainty when performing fault level calculations. That’s why it’s important to use conservative values when designing and operating electrical systems.

Fault Level Calculator

The term “fault level” is used in electrical engineering to refer to the maximum amount of current that can flow through a given circuit without causing damage. In order to determine the fault level of a circuit, engineers use a variety of factors, including the material the conductor is made from, the cross-sectional area of the conductor, and the length of the conductor. Additionally, they must also consider any insulation that may be present.

Once all of these factors have been taken into account, engineers can use a variety of mathematical formulas to calculate the fault level of a circuit. However, it should be noted that these calculations are only estimates; in reality, the actual amount of current that can flow through a circuit before damage occurs will depend on a number of real-world factors, including ambient temperature and humidity.

Fault Level at 132 Kv System

Fault level at 132 kV is the highest voltage that can be applied to a 132 kV system without causing a permanent change in the system. This is typically due to insulation damage or conductor melting. A faulted circuit breaker at this voltage will cause an instantaneous and irreversible loss of power to the affected area.

Fault Level in Power System

Fault level is the maximum amount of electrical current that a power system can carry without sustaining damage. It is an important factor to consider when designing and operating a power system, as it determines the amount of electrical energy that can flow through the system before causing damage.

The fault level of a power system is determined by its component parts, including the conductor material, insulation, and other factors.

The conductor material determines how much current can flow through the system before it begins to heat up and sustain damage. The insulation determines how much current can flow through the system before it causes arcing and sparks. Other factors, such as environmental conditions, also play a role in determining fault level.

Operating at or below the fault level ensures that the power system will not be damaged by electrical energy flowing through it. This protects equipment and personnel from harm and prevents outages that could disrupt service.

Credit: www.chegg.com

What is Substation Fault Level?

A substation fault level is the maximum amount of electrical current that a power system can safely handle without damaging itself. The term is usually used in reference to high-voltage systems, such as those used in electric utilities. Substations contain equipment that steps down the voltage of the electricity so it can be safely used by homes and businesses.

If too much current flows through a substation, it can cause an explosion or fire.

What is the Fault Level of 33Kv Substation?

In an electrical power system, the fault level is the highest voltage that can be created by a short circuit. The term is most often used in high-voltage substations, where the voltages are particularly large.

The fault level of a 33kV substation is 66kV.

This means that if there is a short circuit at the substation, the maximum voltage that can be generated is 66kV.

What is the Fault Level of 11Kv System?

The fault level of 11kV system is determined by the maximum prospective short circuit current (PSC) that can flow through the system. The PSC is a function of the voltage and impedance of the system, and is typically expressed in kVA or MVA.

How Do You Calculate the Fault Level of a Power System?

The fault level of a power system is the highest electric current that can flow through the system under normal conditions. It is usually expressed in amperes (A). The formula for calculating the fault level is:

fault level = I max x Z where:

I max = maximum current that can flow through the system Z = impedance of the system

The maximum current that can flow through a power system is determined by the capacity of the conductor and protection devices.

The impedance of a power system depends on the length and cross sectional area of the conductor, as well as the resistivity of the material.

Conclusion

The purpose of this blog post is to provide information on the fault level of a substation. A substation typically has a much higher fault level than that of the distribution system it serves. This is due to the fact that a substation must be able to clear faults on its own, without relying on other parts of the system.

The high fault level also allows for a greater margin of safety in case of an equipment failure.