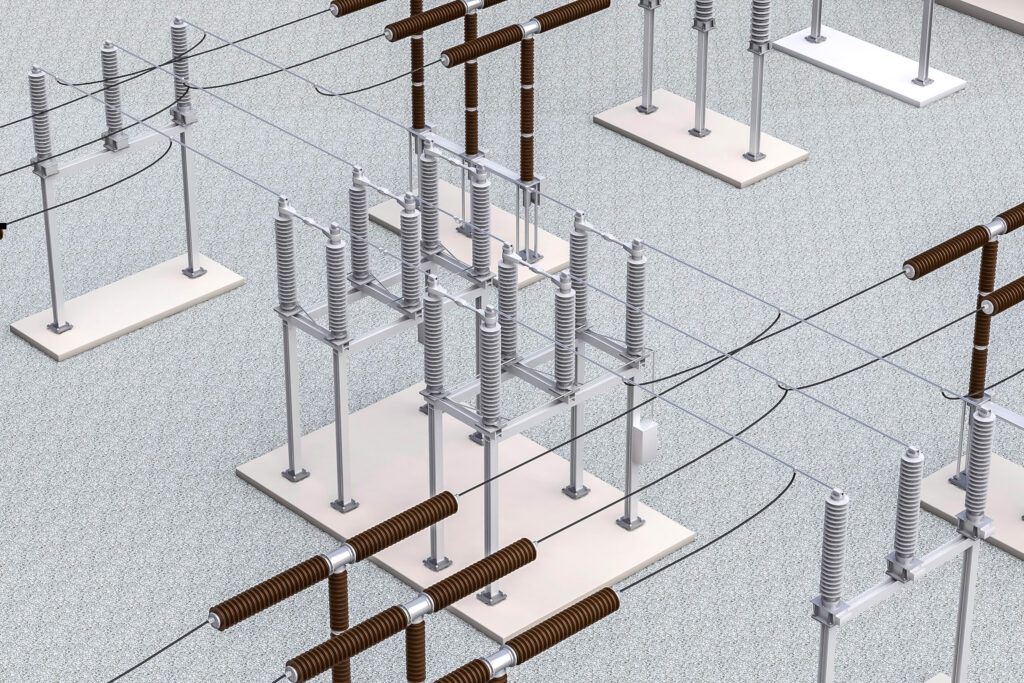

A busbar is an electrical conductor that carries high currents and voltages between devices in a substation. A typical busbar system consists of one or more metal bars, called busbars, mounted on insulators and enclosed in a weather-proof housing. The main function of a busbar is to provide a low-resistance path for electric current.

What is a substation busbar

In a substation, a bus bar is an assembly of copper or aluminum conductors that provides a low-resistance path for the flow of electric current. A bus bar may consist of a single conductor or multiple conductors bundled together. Bus bars are used to connect electrical equipment within a substation and are typically housed in an enclosure known as a switchgear.

The use of bus bars allows for smaller, more efficient substations as compared to those using individual wires to connect electrical equipment. Additionally, bus bars are less likely than individual wires to develop faults due to the increased surface area that results from bundling multiple conductors together.

Function of Busbar in Substation

A busbar is an electrical conductor that connects multiple circuits together. Busbars are typically made of copper or aluminum, and they are used in a variety of electrical applications, including power distribution, circuit protection, and grounding. In a substation, a busbar is used to connect the primary voltage source to the secondary voltage source.

The busbar also provides a connection point for various other devices in the substation, such as transformers, circuit breakers, and disconnects.

Types of Busbar in Substation

A busbar is a metal bar or rod that is used to conduct electricity within a substation. There are three types of busbars that are commonly used in substations: primary, secondary, and tertiary.

Primary busbars are the main source of power for a substation and are typically made from copper or aluminum.

Secondary busbars are used to distribute power from the primary busbars to the rest of the substation components. Tertiary busbars are used to connect emergency backup generators to the substation in case of a power outage.

Electrical Busbar System Pdf

What is an Electrical Busbar System?

An electrical busbar system is a type of electrical distribution system that uses busbars to distribute power. Busbars are metal bars or cables that conduct electricity and are used in a variety of applications, including panelboards, switchgear, and motor control centers.

While busbar systems have been used for many years, they have seen a resurgence in popularity in recent years due to their many advantages over traditional electrical distribution systems.

Advantages of Electrical Busbar Systems

There are many reasons why electrical busbar systems are becoming increasingly popular.

Some of the most notable advantages include:

Increased Efficiency: One of the biggest advantages of using busbars is that they are much more efficient than traditional methods of distributing power. This is because there is very little energy lost as electricity travels through the busbars.

In fact, some estimates show that energy losses can be as low as 2% with properly designed and installed busbar systems. This compares favorably to the 6-10% losses typically seen with copper wire-based distribution systems.

Reduced Costs: The increased efficiency of electrical busbar systems also leads to reduced costs.

Since less energy is lost during transmission, utilities can save money on generation and transmission costs. Additionally, businesses can see reduced energy bills thanks to the improved efficiency provided bybusbars.

Simplified Maintenance: Another big advantageof using electrical busbars is that they simplify maintenance tasks.

With traditional copper wiring-based distribution systems, tracing and repairing faults can be a time-consuming and expensive process. However, since each circuit in abusbar systemis clearly visible, it’s much easierto identifyand fix problems when they occur.

What is Busbar in Electrical

Busbars are an important part of electrical systems. They are used to connect two or more electrical circuits together. Busbars can be made from a variety of materials, but they are most commonly made from copper or aluminum.

Busbars have a number of advantages over other methods of connecting electrical circuits. They are very durable and have a high resistance to corrosion. Additionally, busbars can carry large amounts of current, making them ideal for use in high-power applications.

There are a few things to keep in mind when using busbars in your electrical system. First, it is important to make sure that the busbar you select is rated for the amount of current you plan to run through it. Additionally, you need to ensure that the busbar is properly supported and mounted so that it does not become loose and cause a short circuit.

Electrical Bus Bar Connections

An electrical bus bar is a conductive metal strip or bar that is used to provide a common connection between multiple circuits. A bus bar can be used to connect two or more circuit breakers together, or to connect multiple loads to a single circuit breaker. Bus bars are also used to connect the grounding conductor of an electrical system to the equipment grounding conductor.

There are many different types of bus bars available, including copper, aluminum, and even stainless steel. The material chosen for a particular application will depend on factors such as cost, weight, and corrosion resistance. Copper is the most popular choice for bus bars due to its excellent conductivity and low resistance, but it is also the most expensive option.

Aluminum is a cheaper alternative that offers good conductivity but is not as durable as copper. Stainless steel is often used in corrosive environments because it resists corrosion better than other materials.

When selecting a bus bar for your application, it is important to consider the current carrying capacity and voltage rating of the device.

The current carrying capacity is determined by the cross-sectional area of the bus bar and the material from which it is made. The voltage rating must be equal to or greater than the highest voltage that will be applied to the device.

Busbar Automotive

A busbar is a metal bar or plate used to conduct electricity within a circuit. They are often used in automotive applications, where multiple electrical components are mounted on the same bar or plate. This allows for a more compact and efficient design, as well as reducing wiring costs.

Bus Bar Arrangement in Substation Pdf

A bus bar is an electrical conductor that carries current between different parts of an electrical system. A bus bar can be made of copper, aluminum, or other conductive materials. Bus bars are used in a variety of applications, including power distribution, grounding, and circuit protection.

The term “bus bar arrangement” refers to the way in which multiple bus bars are arranged within an electrical system. The most common arrangements are termed “parallel” and “series.” In a parallel arrangement, each bus bar is connected to the same voltage source but has its own dedicated return path back to the source.

This configuration is often used in high-current applications where each bus bar must be able to handle the full load of the system. In a series arrangement, each bus bar is connected to the next one in line, forming a single loop back to the voltage source. This configuration is typically used in lower-current applications where space is limited and there is no need for each bus bar to be capable of carrying the full load by itself.

The choice of parallel or seriesarrangement will depend on many factors, including the amount of current that needs to be carried, the amount of space available for installation, and the number of voltage sources present in the system.

Credit: electrical-engineering-portal.com

What is a Bus Bar Used For?

A bus bar is an electrical conductor that carries current between different devices in a circuit. It can be made of copper, aluminum, or other conductive materials. Bus bars are used to connect electrical devices such as switches, breakers, and voltage regulators together.

They usually have a thicker cross-section than the wires they are connecting, which helps to reduce resistance and improve conductivity.

What is Busbar And Its Types?

A busbar is a strip of metal or other conductor used to connect electrical components or devices. Busbars can be made from many different materials, including aluminum, copper, and steel. They are often used in high-current applications like switchgear, power distribution panels, and battery banks.

Busbars come in many different shapes and sizes, but they all have one thing in common: they provide a low-resistance path for electrical current.

There are three main types of busbars: flat bars, round bars, and tubular busbars. Flat bars are the most common type of busbar and are typically made from sheet metal that has been bent into shape.

Round bars are less common but offer some advantages over flat bars, such as a lower overall resistance due to their circular cross-section. Tubular busbars are the least common type but offer the best resistance to corrosion and mechanical damage.

What are the Bus Bar Arrangements in the Substation?

In power engineering, a bus bar is a metallic strip or bar that conducts electricity within a substation. Bus bars are typically made of copper or aluminum, and they are used to connect electrical components like circuit breakers and transformers together. The main types of bus bar arrangements in substations are radial, looped, and ring.

Radial bus bars are the most common type of arrangement, and they are typically used in smaller substations. In this arrangement, the bus bars run from the center of the substation out to each of the electrical components. This type of arrangement is simple and easy to maintain, but it does have some drawbacks.

One drawback is that if one component fails, the entire system can go down. Another drawback is that radial bus bars can be overloaded during high demand periods.

Looped bus bars are another common type of arrangement, and they offer some advantages over radial arrangements.

Loopbus systems provide multiple paths for electricity to flow, so if one component fails, the other components can still function. This redundancy increases reliability and helps prevent blackouts. Loopbus systems also distribute load more evenly than radial systems, which can help prevent overloads during high demand periods.

Ring busbars are less common than radial or looped arrangements, but they offer some distinct advantages. Ring arrangements provide even more redundancy than looped arrangements, so they are even more resistant to blackouts caused by component failures.

Why is It Called a Bus Bar?

A bus bar is a conductor that connects multiple electrical devices together. The term “bus bar” comes from the Latin word “bussa,” which means “box.” Bus bars are often used to connect circuit breakers, transformers, and other electrical equipment together.

They are also used to distribute power in data centers and other large facilities. Bus bars can be made from a variety of materials, including copper, aluminum, and steel.

Conclusion

A busbar is an electrical conductor that connects multiple circuits together. It is usually made of copper or aluminum and can be either bare or insulated. Busbars are used in a variety of applications, including substations, switchgear, and panelboards.

In a substation, busbars are used to connect the primary voltage source to the secondary voltage source. In switchgear, busbars are used to connect the various components of the electrical system. In panelboards, busbars are used to distribute power to the various circuits.