Substation automation is the use of electronic devices and software to control and monitor the electrical equipment in a substation. Automation can be used to improve the reliability, efficiency, and safety of a substation.

Substation Automation (IEC 61850) SAS by Er. Nandakumar

Substation automation is a process where the controls for a substation are automated. This can include everything from the control room to the field devices. There are many benefits to automating a substation, including improved safety, increased efficiency and reduced costs.

Substation Automation System Pdf

Substation automation systems are designed to improve the efficiency and reliability of power grid operations. By automating key functions such as monitoring, control, and protection, these systems can help utilities optimize performance and reduce costs. This blog post provides an overview of substation automation system basics, benefits, and challenges.

Substation Automation System Ppt

The substation automation system is an important part of the power grid. It controls and monitors the distribution of electricity from the power plant to the end user. The system is designed to protect equipment and personnel, as well as improve efficiency and reliability.

Substation Automation System Abb

An substation automation system (SAS) is a computer-based system used to remotely monitor and control electric power substations. The key components of an SAS are the master station, remote terminal units (RTUs), intelligent electronic devices (IEDs), and communication networks.

The primary benefits of an SAS are improved safety, reliability, and efficiency.

By automating the monitoring and control of substation equipment, SASs help reduce the need for human intervention in potentially hazardous situations. Additionally, SASs can provide real-time data that can be used to improve grid operations and asset management.

ABB offers a comprehensive portfolio of products and solutions for substation automation, including master stations, RTUs, IEDs, communication systems, and software.

Our solutions are designed to meet the specific needs of each customer while providing the highest levels of safety, security, and reliability.

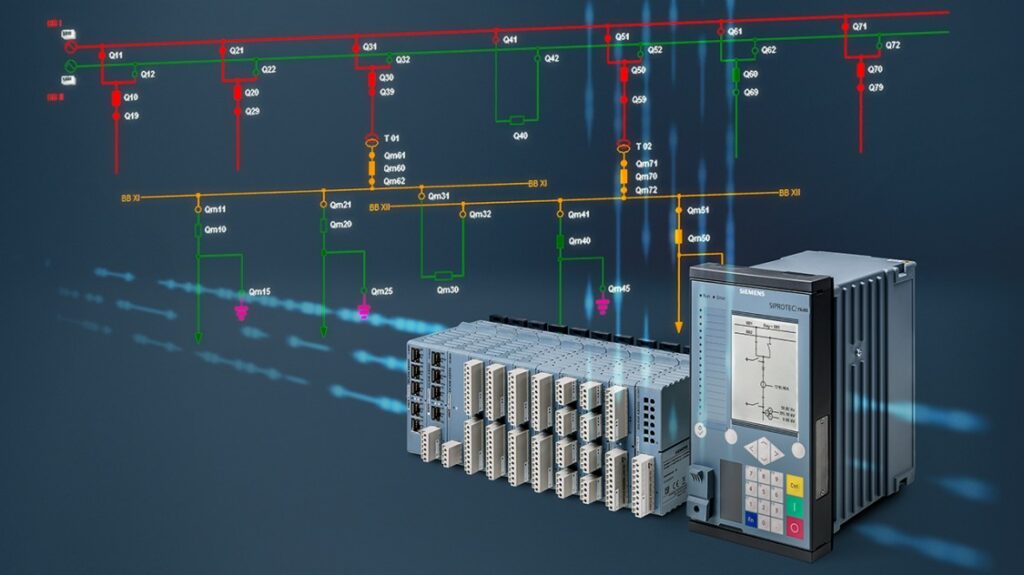

Substation Automation System Siemens

Substation Automation System Siemens

In a substation, the automation system performs the following functions:

-Monitors and controls the equipment in the substation

-Communicates with other systems to exchange information

-Provides an interface for operators

-Protects the equipment in the substation against faults.

The Siemens Substation Automation System is based on standard IEC 61850 protocols and can be integrated into any existing network. The system is highly scalable and can be adapted to the specific needs of each substation.

Substation Automation System Tutorial

A substation automation system is a computer-based system that monitors and controls the electrical equipment in a substation. It consists of various subsystems, such as a control center, data acquisition, and communication systems. The control center is the heart of the substation automation system where all the information from the various subsystems is processed and monitored.

Data acquisition systems collect data from various sources, such as sensors, meters, and switchgear. Communication systems provide two-way communication between the control center and other parts of the substation automation system.

Substation Automation System Protocol

Substation automation systems (SAS) are used to manage and control substations remotely. They typically use a variety of protocols to communicate with devices in the substation, including IEC 61850, Modbus, and DNP3. In this blog post, we’ll take a closer look at each of these protocols and how they’re used in SAS applications.

IEC 61850 is a communication protocol specifically designed for electric power systems. It’s widely used in substation automation and other applications where high levels of reliability are required. IEC 61850 provides many benefits over traditional protocols like Modbus, including better performance and scalability.

Modbus is another popular protocol for substation automation and other industrial applications. It’s been around for longer than IEC 61850 and is therefore more widely adopted. Modbus is simpler than IEC 61850 and thus easier to implement.

However, it doesn’t provide the same level of performance or reliability.

DNP3 is a newer protocol that’s gaining popularity in the substation automation world. DNP3 is designed to be highly interoperable with other protocols like Modbus and IEC 61850.

It offers many of the same benefits as IEC 61850, but with even better performance thanks to its modern design.

Substation Automation System Course

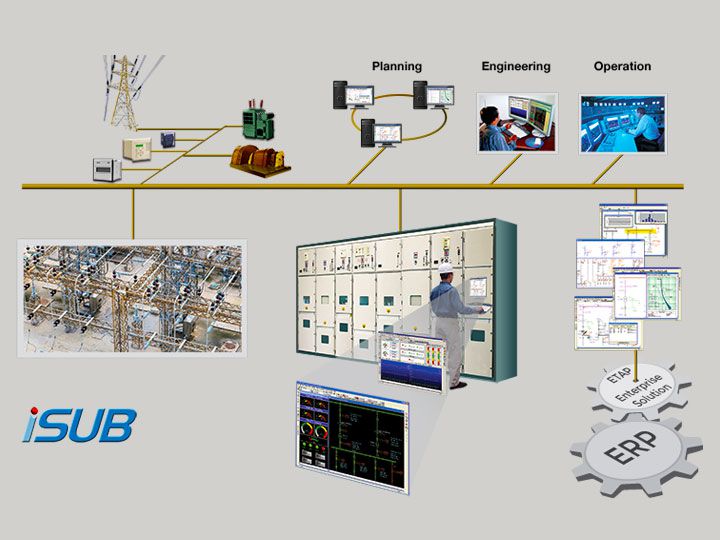

Substation automation system (SAS) is a comprehensive, integrated solution that helps you remotely monitor, control and manage your substation assets. This two-day course provides an overview of the features and benefits of the SAS, as well as how to configure and use it. You’ll learn about the various SAS components, such as the web interface, database server and historian.

You’ll also get hands-on experience with setting up an SAS environment and using the various tools to troubleshoot problems.

Credit: etap.com

How Does Substation Automation Work?

A substation is an electrical power switching and distribution center. Substations are typically located where transmission lines connect to generate electricity at a power plant and deliver it to consumers. A substation can also be located where two or more transmission lines intersect, providing a location for switching between them.

The primary purpose of a substation is to switch or transform electricity from one voltage level to another.

Substation automation is the process of using computer-based intelligence to manage equipment and processes within a substation. This can include automating the control of switches, breakers, and other devices; monitoring equipment conditions; managing data acquisition; and providing interfaces for human operators.

The benefits of substation automation include improved safety, reliability, and efficiency. Automated systems can respond faster than humans to abnormal conditions, preventing or minimizing damage to equipment. They can also provide better coordination between different devices within the substation, leading to improved power flow control and energy utilization.

What are the Main Three Levels of Substation Automation System?

There are three main levels of substation automation system, each with its own capabilities and benefits:

-Basic level: A basic automated substation has supervisory control and data acquisition (SCADA) capabilities, which allow for the monitoring and control of the equipment within the substation. This level of automation can improve efficiency and help to avoid potential problems by providing early warning of issues.

Additionally, SCADA systems can provide valuable data that can be used to improve operations.

-Intermediate level: An intermediate automated substation adds features such as protection scheme management, energy management system integration, and automatic generation control (AGC). These additional capabilities allow for more comprehensive monitoring and control of the substation, as well as improved coordination between different subsystems.

This can lead to even greater efficiency gains and operational improvements.

-Advanced level: The most advanced automated substations also include features such as distributed energy resources (DER) management, demand response integration, and real-time grid monitoring. These cutting-edge features allow for an unprecedented level of visibility into the operation of the substation and the surrounding grid.

Additionally, they enable new applications such as DER aggregation and virtual power plants.

What is the Standard for Substation Automation?

There is no definitive answer to this question as the standard for substation automation can vary depending on the specific requirements of each individual substation. However, in general, a substation automation system should be able to perform the following functions:

-Monitor and control all equipment within the substation

-Communicate with other local and remote devices

-Detect and isolate faults

-Restore service quickly after an outage

-Provide data for analysis and decision making purposes.

A good substation automation system will improve the overall efficiency and reliability of a power grid by reducing downtime, minimizing human error and maximizing coordination between different parts of the system.

What are the Elements of Substation Automation System?

A substation automation system is a combination of hardware and software that is used to control, monitor and protect equipment in a substation. The system typically includes sensors, logic controllers, human-machine interfaces (HMIs) and communication networks.

Substation automation systems are used to improve the reliability and efficiency of power delivery by automating processes that were previously manual.

For example, the system can automatically open or close breakers in response to changes in grid conditions. This reduces the need for human intervention, which can help to reduce errors and improve response times.

The elements of a substation automation system vary depending on the specific application, but typically include some or all of the following:

-Sensors: These are used to measure various parameters such as voltage, current, temperature and pressure. The type of sensor used will depend on the quantity being measured. For example, current transformers are commonly used to measure currents while thermocouples are used to measure temperatures.

-Logic controllers: These interpret the signals from the sensors and make decisions based on predefined rules. For example, a logic controller may compare voltages from two different parts of the grid and take action if it detects an imbalance.

-Human-machine interfaces (HMIs): These provide a graphical interface that allows operators to view information about the substation and interact with the system.

HMIs can be simple displays that show real-time data or more complex interfaces that allow operators to control equipment remotely.

-Communication networks: These connect all of the devices in the substation so that they can communicate with each other.

Conclusion

The blog post discusses the automation of substations. It describes the various benefits of automating a substation, such as improved safety, efficiency, and reliability. It also outlines the challenges that need to be overcome in order to successfully automate a substation.