In a factory substation, the required equipment includes a transformer for stepping down the voltage from the main power supply, circuit breakers for each of the outgoing feeders, and metering equipment. The substation may also have an emergency generator to provide power in case of a outage.

A factory substation is a power substation located on the premises of a large industrial facility. A factory substation may be owned and operated by the facility it serves, or it may be owned and operated by an electric utility. The primary purpose of a factory substation is to distribute electricity to the various loads within the facility.

The secondary purpose of a factory substation is to provide voltage transformation. That is, the incoming high voltage from the utility is stepped down to a lower voltage that can be used safely by the loads within the facility. The outgoing line from the factory substation will usually carry this lower voltage back to the utility grid.

Factory substations typically contain one or more transformers, circuit breakers, and disconnect switches. The transformer(s) steps down (or up) the voltage from the utility line to a level that can be used by the loads within the facility. The circuit breaker(s) protect both the equipment in the substation as well as downstream equipment from faults on either side of them.

And finally,the disconnect switch(es) provide a way to physically disconnect certain parts ofthe substation (and/or connected load) for maintenance purposes.

In some cases, factory substations may also house other devices such as reclosers, metering equipment, relays, etc.

Substation Equipment List

Substation equipment is used in the electrical power industry to help protect and control the flow of electricity. This equipment is critical in ensuring the safety of workers and the public, as well as maintaining the quality of power supply. The following is a list of common substation equipment:

-Circuit breakers: Used to open and close circuits, circuit breakers are one of the most important pieces of substation equipment. They are available in both air and oil-filled varieties.

-Transformers: These devices convert voltage from high to low or vice versa, depending on the needs of the system.

-Capacitors: Capacitors store energy and release it when needed to help stabilize voltage levels.

-Reactors: Reactors are used to limit current flow in a circuit.

This is just a brief overview of some of the most essential substation equipment.

For more detailed information on any of these items, please consult with an expert in the field.

Substation Equipment Pdf

A substation is a critical part of the electric power grid. Substations transform voltage from high to low, or the reverse, and distribute power around an electric grid. They also house equipment that helps to protect against power surges and blackouts.

There are three main types of substations: transmission, distribution, and combined. Transmission substations connect different parts of the high-voltage transmission system, while distribution substations take electricity from the transmission system and lower the voltage so it can be distributed to customers. Combined substations perform both functions.

Most substations are above ground, although some may be underground or even underwater (for example, in case of flooding). The enclosure houses all of the electrical equipment inside, including switchgear,transformers, circuit breakers, and other devices. Substations may also have monitoring and control systems to help manage the flow of electricity across the grid.

The first step in designing a new substation is understanding the loads that will be placed on it – for example, how much electricity will need to be transformed? What is the maximum amount of current that could flow through any given piece of equipment? Once these loads are understood, engineers can determine what type(s)of equipment are needed inside the substation enclosure as well as how it should all be laid out.

The next step is to select a site for the new substation. This process takes into account many factors such as land availability ,proximity to existing infrastructure , environmental impacts , zoning regulations ,and cost . After a site has been selected ,the necessary permits must be obtained before construction can begin .

Transformer Equipment List

When it comes to industrial transformer equipment, there are a few key pieces that are essential for proper function. Here is a basic list of what you’ll need:

-A primary winding.

This is the part of the transformer that receives power from the source.

-A secondary winding. This is the part of the transformer that provides power to the load.

-An iron core. This helps to concentrate and redirect magnetic flux, which is important for proper transformer operation.

-Insulation material.

This helps to keep electrical current from flowing where it shouldn’t, and also helps to protect against mechanical damage.

Substation Parts And Equipment

A substation is a critical part of the electrical grid. It is a collection of equipment that transforms, switches, and controls the flow of electricity. Substations come in a variety of sizes and configurations, but all have three basic components: transformers, switchgear, and control equipment.

Transformers are used to step up or step down voltage levels. Switchgear is used to connect and disconnect circuits. Control equipment monitors and regulates the flow of electricity through the substation.

Substations play a vital role in keeping the power flowing to homes and businesses. Without them, the electrical grid would not be able to function properly.

33/11Kv Substation Equipment Pdf

A 33/11kV substation is a high voltage electrical substation where the voltages are converted from 11kV to 33kV. This conversion is necessary because the equipment in a substation can only operate at certain voltages. The 11kV voltage is too low for some of the equipment, so it must be increased to 33kV.

The main piece of equipment in a 33/11kv substation is the transformer. The transformer increases the voltage from 11kv to 33 kv. The transformer also has two windings, one for the incoming voltage and one for the outgoing voltage.

The other main piece of equipment in a substation is the switchgear. The switchgear controls the flow of electricity through the substation.

There are several types of transformers that can be used in a 33/11 kv substation.

The most common type of transformer is the oil-filled transformer. Oil-filled transformers are filled with oil, which helps to cool them down and prevent them from overheating. Another type of transformer that can be used is the dry-type transformer.

Dry-type transformers do not use oil, and they are typically smaller than oil-filled transformers.

The switchgear in a substation can either be air-insulated or gas-insulated.

Substation Equipment Ppt

As the name suggests, substation equipment is used in electrical substations. They are generally high voltage and current devices that are used to switch, protect and transform electrical energy. Substations can be found all over the world, from small rural villages to large cities.

Substation equipment includes:

-Circuit breakers

-Transformers

-Isolators

-Capacitors

Circuit breakers are one of the most important pieces of equipment in a substation.

Their primary function is to interrupt the flow of electricity in an emergency situation, such as when a power line is damaged or a transformer overheats. Circuit breakers can either be manually operated or remotely controlled.

Transformers are used to change the voltage of electricity passing through them.

This is necessary because different parts of the electrical grid operate at different voltages. For example, transmission lines carry electricity at very high voltages (usually 115 kV or more), while distribution lines carry it at lower voltages (typically between 4 kV and 35 kV). Isolators are used to isolate sections of the substation so that maintenance can be carried out on one section without affecting the rest of the substation.

Capacitors are used to store electric charge and help regulate voltage levels in the substation.

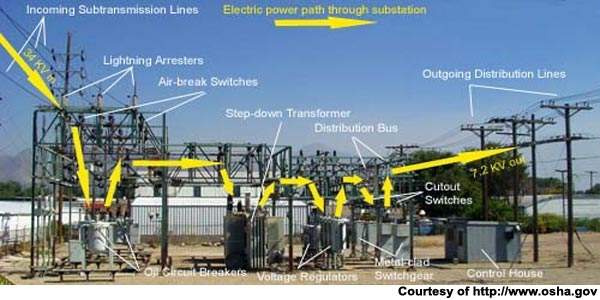

Credit: www.osha.gov

Which Equipment are Used in Substation?

In a substation, various types of equipment are used for different purposes. Some of the most common pieces of equipment found in a substation include:

-Transformers: Transformers are used to change the voltage of electricity passing through the substation.

This is done by using coils of wire to increase or decrease the amount of magnetic flux passing through the transformer’s core.

-Circuit breakers: Circuit breakers are used to protect transformers and other equipment in the substation from damage due to electrical faults. When an electrical fault occurs, circuit breakers open up and stop the flow of electricity to prevent further damage.

-Capacitors: Capacitors are used to store electric charge and help improve power quality by providing a smooth flow of current.

-Reactors: Reactors are devices that help control the flow of electricity by creating inductance. This is done by wrapping coils of wire around a ferromagnetic material such as iron.

-Busbars: Busbars are large metal bars that conduct electricity between different parts of the substation. They are often made from copper or aluminum and can carry very large currents.

What are the Main Equipments And Circuit Elements of Substations?

Substation Equipment

The main equipment in a substation are the transformers, circuit breakers, and buses. The transformers change the voltage from the high voltage of the transmission line to the lower voltage used by the distribution system or customer loads.

The circuit breakers protect equipment and conductors by opening and closing circuits as needed. The buses connect all of the substation equipment together.

Which is the First Equipment Installed in Substation?

The first equipment installed in a substation is typically the switchgear. This equipment includes the circuit breakers, switches, and other devices that control the flow of electricity within the substation. The switchgear is responsible for protecting the substation equipment from damage due to electrical faults.

What are the Three Main Components of a Unit Substation?

Unit substations are an important part of the electrical grid, providing a safe and reliable way to connect different parts of the system. They are typically used to connect high-voltage transmission lines to lower-voltage distribution lines, or to provide service for large loads that require a lot of power.

Substations come in all shapes and sizes, but they all have three main components: the transformer, switchgear, and metering equipment.

The transformer is the most important component of a substation, as it transforms the high-voltage electricity from the transmission lines into a lower voltage that can be used by homes and businesses. The switchgear controls the flow of electricity through the substation, and the metering equipment monitors power consumption and keeps track of how much electricity is being produced or consumed.

Without these three essential components, a unit substation would not be able to function properly – and neither would the electrical grid as a whole!

How Do Substations Work?

Conclusion

Most factories will require some form of equipment in their substations. This can include anything from large pieces of machinery to smaller tools and devices. The type of equipment required will vary depending on the size and type of factory, as well as the specific needs of the business.

However, there are a few essential items that most factories will need to function properly.