A digital fault recorder (DFR) is a device that uses digital technology to record and store data related to electrical faults at substations. This data can be used to help utilities identify and correct problems, improve operations, and make informed decisions about equipment upgrades and maintenance. DFRs are typically installed near the breaker panels in substations, and they are connected to the power system through special sensors called current transformers (CTs).

When a CT senses a change in current flow that indicates a fault, it triggers the DFR to begin recording data. The DFR continues to record data for a pre-determined period of time after the fault has cleared, allowing utility engineers to review the event and make necessary changes to improve system performance.

Digital fault recorders are used in substations to record and store data about faults that occur on the electrical grid. This data can be used by engineers to investigate and troubleshoot problems with the grid. Digital fault recorders are typically installed at high-voltage substations, where they can monitor conditions and provide information about faults that occur.

Digital Fault Recorders | How DFR Work | Technology Types | DFR Advantages | Power System Operation

Digital Fault Recorder Siemens

Digital fault recorders (DFRs) are devices that monitor and record electrical faults on power systems. They are used to help utilities and power system operators troubleshoot system problems, identify trends, and improve reliability.

Siemens is a leading manufacturer of DFRs, with over 30 years of experience in the industry.

The company offers a wide range of products to meet the needs of various applications, from small substations to large-scale transmission and distribution networks.

The Siemens SIRIUS range of DFRs is one of the most popular choices for utilities around the world. It includes a variety of models that offer different features and options to suit different requirements.

For example, the SIRIUS 3RW5 DFR is designed for use in medium-voltage switchgear, while the SIRIUS 3RW52 is suitable for monitoring high-voltage AC and DC systems.

DFRS are an important part of any power system, providing valuable data that can be used to improve reliability and performance. If you’re looking for a DFR solution for your application, Siemens is a great option to consider.

Digital Fault Recorder Qualitrol

Digital Fault Recorders (DFRs) are devices that monitor and record the electrical current flowing through a power system. They are used to troubleshoot electrical problems, identify equipment faults, and track performance trends. Qualitrol is a leading manufacturer of DFRs.

Digital fault recorders can be used in a variety of applications, including:

-Troubleshooting electrical problems

-Identifying equipment faults

-Tracking performance trends

-Monitoring power quality

-Detecting harmonics

DFRS differ from other monitoring devices in that they provide a high degree of accuracy and detail. This is made possible by their use of digital technology instead of analog. Digital fault recorders are more expensive than their analog counterparts, but they offer many advantages, such as:

Sel Digital Fault Recorder

Digital Fault Recorders (DFRs) are devices that continuously monitor and record the condition of electrical equipment. The records can be used to determine the cause of faults, and to provide evidence for insurance claims or other legal proceedings.

DFRs are often used on high-voltage power lines, where they can provide valuable information about the causes of line failures.

They are also used in industrial plants, where they can help to identify problems with machinery before they lead to costly downtime.

DFRs typically have a number of input channels, which can be connected to various sensors and monitoring devices. They also have a variety of output options, which allow the records to be printed, emailed or transmitted over a network.

When choosing a DFR, it is important to consider the type of equipment that will be monitored, and the specific needs of your application.

Disturbance Recorder in Substation

In a substation, a disturbance recorder is a device that monitors and records voltage and current values during abnormal conditions. It is used to investigate system disturbances and help determine the cause of the problem.

The recorder consists of three main parts: the sensing element, which measures voltage and current; the data acquisition unit, which digitizes the measured values; and the storage unit, which stores the digitized values.

The sensing element is typically a transformer or Rogowski coil. The data acquisition unit converts the analog signal from the sensor into digital form so it can be stored on a computer or other storage device. The storage unit can be internal to the recorder or external, such as a USB flash drive.

Recorders are used in conjunction with other devices, such as transducers, to measure various parameters in order to understand system behavior during disturbances. Disturbance recorders are an important tool for power system engineers when investigating problems with electrical equipment.

Dfr Electrical

DFR electrical is a mode of operation for an electrical system that involves using direct current to supply power to the system. The main advantage of this method is that it eliminates the need for an inverter, which can be expensive and complicated to maintain. Additionally, DFR systems are typically more efficient than their alternating current counterparts.

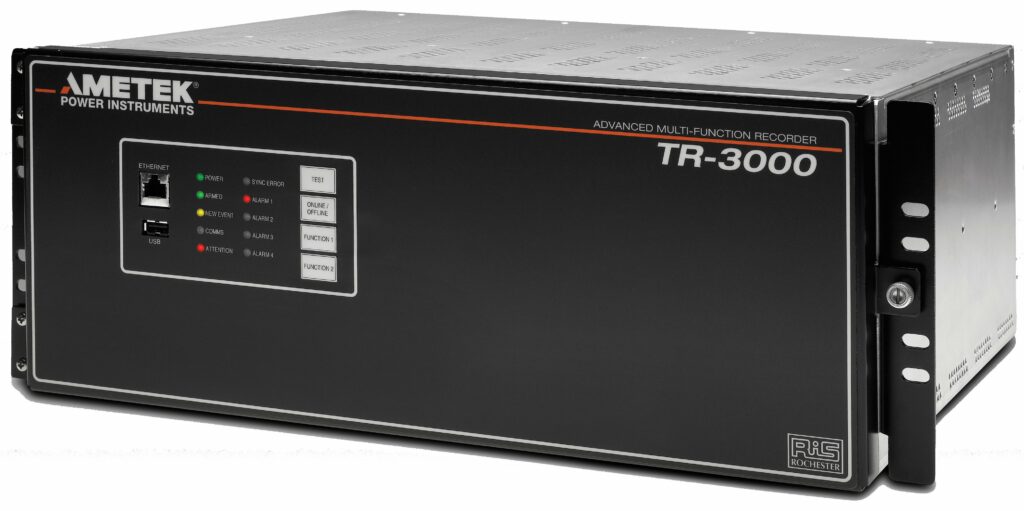

Ametek Fault Recorder

An Ametek fault recorder is a device that is used to record data about electrical faults. This data can be used to help diagnose and repair electrical problems. The Ametek fault recorder is a portable, handheld device that can be used to record data on up to three channels simultaneously.

The device has a built-in memory that can store up to one hour of data, and it also has a USB port that can be used to transfer data to a computer for analysis.

Transient Fault Recorder

Transient Fault Recorder is a tool that can be used to record and store data about faults that occur in software or hardware. This information can be used to help diagnose and fix the problem. Transient Fault Recorder can be used to record data about:

-Faults that occur in software or hardware

-The type of fault (e.g., CPU, memory, I/O)

-When the fault occurred

-What was happening at the time the fault occurred

This information can be very useful when trying to diagnose and fix a problem. In many cases, it can be difficult to reproduce a transient fault.

But if you have recorded data from the Transient Fault Recorder, you may be able to find patterns that will help you identify the cause of the problem.

Rpv311

Rpv311, also known as 3-((1-(2-methoxyethyl)-3-methylbutyl)carbamoyl)-2,2-dimethylpropanoic acid, is a potent and selective inhibitor of the mitotic kinesin Eg5. Inhibition of Eg5 prevents cell division and leads to cell death. Rpv311 has shown efficacy in multiple cancer types including ovarian, breast, lung, and brain cancers.

Credit: satec-global.com.au

What is a Digital Fault Recorder?

A digital fault recorder is a device that monitors and records the electrical current flowing through a power system. It is used to detect, diagnose, and investigate faults in the system. The recorder measures the voltage and current waveforms, as well as the frequency and phase angle of the waveforms.

It then stores this information in a digital format for later analysis.

The digital fault recorder has several advantages over traditional analog recorders. First, it can store more information in a given period of time.

Second, it is easier to retrieve and analyze the data stored in a digital format. Third, the digital recorder can be interfaced with other devices and systems for further analysis. Finally, because the digital recorder uses less power than an analog recorder, it can be used in portable applications.

What is the Purpose of Fault Recording?

Fault recording is the process of capturing information about faults in a system. This information can be used to troubleshoot problems, determine root cause, and track trends over time. Fault recording can be performed manually or automatically, and may include data such as date/time stamp, severity, component affected, and description of the issue.

What is the Price of Digital Fault Recorder?

Digital fault recorders are devices that are used to record and store data about electrical faults. These devices can be used to investigate and diagnose problems with electrical equipment and systems. The price of digital fault recorders can vary depending on the features and specifications of the device.

Some digital fault recorders can cost as little as $100, while others may cost several thousand dollars.

Conclusion

In a substation, a digital fault recorder (DFR) is a device that continuously monitors the electrical parameters of the system and automatically records any event that exceeds preset limits. The recorded events can then be analyzed to help determine the cause of the faults.

A DFR typically consists of three parts:

– Sensors: These are used to measure the electrical parameters of the system, such as voltage, current, and frequency.

– Data acquisition unit: This unit converts the analog signals from the sensors into digital data that can be stored on a memory card or hard drive.

– Analysis software: This software is used to analyze the recorded data and generate reports.