A Scada Substation Automation system is a computerized system that monitors and controls the electrical equipment in a substation. This system provides real-time information about the equipment’s performance and health, and can automatically control switching operations and other functions.

HOW TO WORK SCADA, SCADA SYSTEM, 132/33 SUBSTATION, NEW SCADA SYSTEM

Substation automation is the application of automated controls to substations. Substation automation systems can be used for a variety of purposes, including monitoring and control of equipment, asset management, and grid operations. A typical substation automation system includes a variety of sensors, controllers, and communication devices that are connected to a central management system.

Substation automation offers many benefits over traditional manual or semi-automatic control systems. Automated systems can provide real-time data on equipment performance and conditions, allowing for more effective monitoring and control. Additionally, automated systems can improve safety by reducing the need for human intervention in potentially hazardous situations.

Moreover, substation automation can help utilities optimize grid operations by providing information that can be used to make decisions about power flow and other factors.

Despite the many advantages of substation automation, there are also some challenges that must be considered when implementing such systems. One challenge is the cost of investment; while automated systems offer significant long-term benefits, they require upfront capital expenditure that may be difficult to justify in some cases.

Additionally, automated systems introduce new complexities that must be managed effectively; for example, ensuring proper cybersecurity protections are in place is critical to protecting against malicious attacks that could jeopardize power delivery or cause other disruptions.

Substation Automation System Pdf

A substation automation system is a computerized system that monitors and controls the electrical equipment in a substation. This system provides real-time information about the equipment and its operating conditions, and can be used to control the equipment remotely.

The benefits of a substation automation system include improved safety, reliability, and efficiency.

By providing real-time information about the equipment and its operating conditions, this system can help reduce downtime and improve response time to faults. In addition, automated systems can provide remote data collection capabilities for analysis and trending purposes.

There are many different types of substation automation systems available on the market today.

Some of these systems are designed specifically for use with certain types of equipment, while others are more general purpose. When choosing a substation automation system, it is important to select one that is compatible with the specific types of equipment in your substation as well as your budget.

Substation Automation System Abb

Substation automation system (SAS) is a solution that helps utilities to remotely monitor, control and protect substations. It also provides data for network analysis and asset management. The SAS consists of various devices, software and networking components that enable two-way communication between the substation and the utility control center.

The main benefits of using a SAS are:

-Improved safety: By automating tasks that were previously carried out manually, there is less need for personnel to enter potentially hazardous areas. In addition, automated monitoring can help identify potential problems before they cause an incident.

-Reduced costs: Automation can help reduce operating costs by reducing the need for manual labor, as well as improve efficiency through real-time data collection and analysis.

-Increased reliability: Automated systems can provide more accurate information about the status of equipment and conditions in the substation, which can help reduce unplanned outages caused by human error.

-Better visibility into operations: A SAS can provide detailed information about all aspects of substation operations, including power flows, transformer loading levels and circuit breaker status.

This visibility can help identify issues before they cause problems and allow for proactive maintenance.

Substation Automation System Tutorial

Substation automation systems are used to control, monitor and protect substations. They provide real-time data that helps utilities make better decisions about grid operations. This tutorial will provide an overview of substation automation systems, including their history, how they work and their benefits.

Substation Automation System Protocol

Substation Automation System Protocol is a set of communication protocols used for the operation, maintenance and management of substations. It is based on the international standard IEC 61850. The protocol enables interoperability between different manufacturers’ equipment and systems.

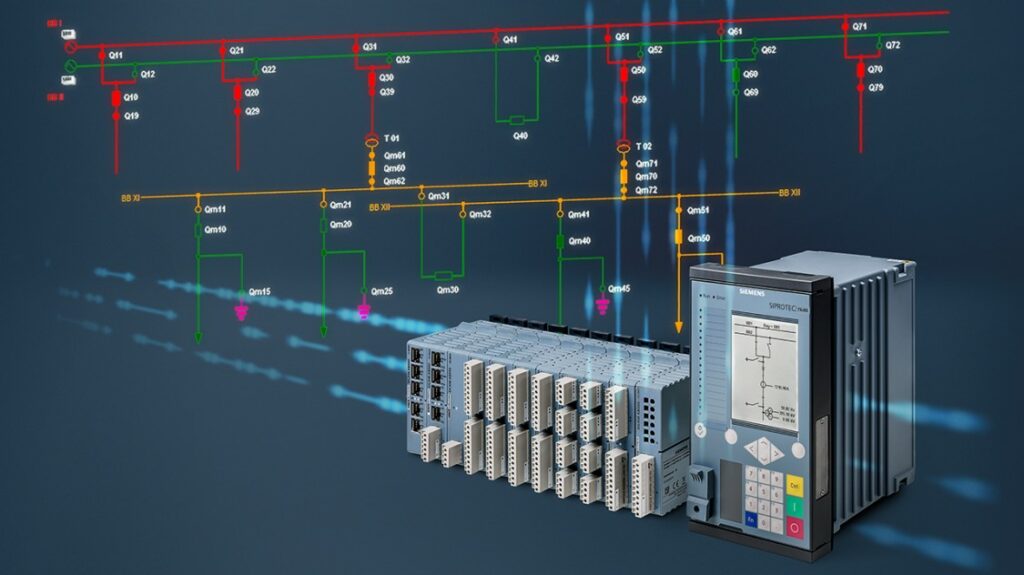

Substation Automation System Architecture

Substation automation systems are used to improve the efficiency, safety, and reliability of electric power substations. They typically consist of a combination of hardware and software that is installed at the substation. The system architecture can vary depending on the specific needs of the substation, but all systems share some common components.

The most important component of a substation automation system is the control center. This is where operators can monitor and control all aspects of the substation. The control center typically has a large display screen that shows real-time data from various sensors and equipment in the substation.

It also has several input devices, such as keyboards and mice, that allow operators to interact with the system.

Another important component of a substation automation system is the communication network. This network connects all of the devices in the substation so that they can communicate with each other.

The communication network may be wired or wireless, and it may use different protocols depending on the specific requirements of the substation.

In addition to these two main components, a typical substation automation system will also have several other smaller components, such as sensors, actuators, relays, meters, and breakers. These devices are connected to the control center via the communication network and are used to collect data about conditions in the substation or to perform certain actions based on commands from operators.

Components of Substation Automation System

In a substation, the automation system consists of several components that work together to provide an automated solution. These components include:

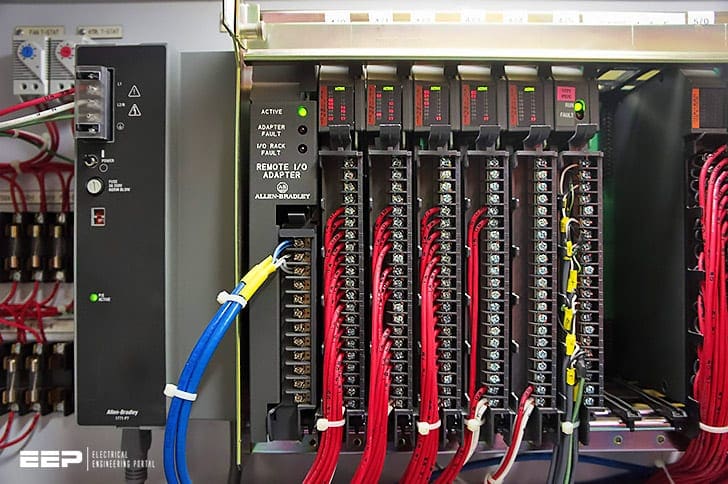

-I/O (Input/Output) Modules: These modules are responsible for interfacing with the various devices in the substation, such as sensors, actuators, and switchgear.

They provide the means for these devices to communicate with the automation system.

-Processors: The processors are responsible for executing the algorithms that have been programmed into the automation system. They make decisions based on the data received from the I/O modules and execute the commands sent to them by those modules.

-Communications: The communications component of the automation system is responsible for transmitting data between the various subsystems within the substation. This data may be transmitted over optical fiber, twisted pair cable, or radio waves.

-Power Supply: The power supply provides power to all of the other components in the substation automation system.

Substation Automation System Ppt

Substation automation system is a computer based system that controls, monitors and operates the electrical equipment in a substation. It is an integrated system that uses various technologies such as supervisory control and data acquisition (SCADA), programmable logic controllers (PLCs), remote terminal units (RTUs) and distribution management systems (DMSs).

A substation automation system provides many benefits such as increased efficiency, improved safety, reduced costs and better asset management.

It also helps in improving the quality of power supply, reducing outages and enhancing grid stability.

Credit: electrical-engineering-portal.com

What are the Three Levels of Substation Automation?

Substation automation is the process of using technology to control and monitor the equipment in a substation. There are three levels of substation automation:

1. Basic automation – This level includes features such as automatic voltage regulation, circuit breaker status monitoring, and remote control of equipment.

2. Medium automation – In addition to the features of basic automation, medium automation includes features such as energy management and load forecasting.

3. Advanced Automation – The most sophisticated level of substation automation, advanced automation includes features such as condition-based maintenance and real-time monitoring of equipment performance.

What is the Importance of Scada in Substation?

In electric power systems, a substation is a facility where voltage is transformed from high to low, or the reverse, using transformers. A substation may also include switches that allow electricity to be redirected. The word “substation” can refer to either the physical structure housing those components or the components themselves.

The primary purpose of a substation is to switch electrical energy from one transmission path to another without interrupting the flow of energy in either direction. Substations are used for changing the voltage of electricity flowing in long-distance transmission lines so it can be more efficiently utilized by local distribution systems. They also provide switching operations for repairing sections of transmission lines and for connecting generators and loads to the grid.

In addition, many substations now house equipment that monitors and controls the electric power system remotely via supervisory control and data acquisition (SCADA) systems.

Substations are typically located near large load centers such as cities or factories, or at strategic points along an interconnected grid where lines connect with other lines at different voltages. A typical substation includes:

-A set of high-voltage breakers and/or disconnects that isolate parts of the substation for maintenance

-One or more transformers that change voltages between transmission levels (138 kV, 115 kV, 69 kV…)and lower distribution levels (13 kV, 4 kV…)

-Protective relays that detect faults on circuits and automatically open breakers to isolate problems

-Metering devices that measure current, voltage, and power flowing in the circuit

-Communication equipment such as radios or landlines for coordinating repair crews during outages

SCADA systems play an important role in monitoring and controlling all aspects of a substation’s operation from a central location.

This allows operators to quickly identify problems and take corrective action before major damage occurs. Additionally, SCADA data can be used to trend conditions over time so that potential issues can be detected early and addressed before they cause problems..

How Does Substation Automation Work?

Substation automation is the process of automating the various tasks and processes associated with substations. This includes the monitoring and control of equipment, as well as the coordination of activities between different stakeholders.

Substation automation systems typically consist of a variety of sensors, controllers, and other devices that are connected to a central control system.

This system gathers data from the various devices and uses it to monitor and control the substation equipment. The controller can also be used to coordinate activities between different stakeholders, such as dispatchers, operators, and maintenance personnel.

One of the benefits of substation automation is that it can help to improve the efficiency of operations by reducing or eliminating manual tasks.

Automation can also help to improve safety by reducing the need for human intervention in potentially hazardous situations. Additionally, substation automation can help to improve reliability by providing accurate and up-to-date information about conditions at the substation.

What is Automation of Mv Substations?

An MV substation is an electrical substation that uses medium voltage for its operation. Medium voltage is any voltage between 1 kV and 36 kV. Automation of MV substations refers to the use of electronic devices and software to control and monitor the operations of an MV substation.

This can include automatic monitoring and control of voltages, currents, and other parameters, as well as automated generation of reports on the status of the substation. The use of automation can improve the efficiency and safety of MV substations, as well as reducing the need for manual intervention.

Conclusion

The post discusses the various benefits of SCADA substation automation. These benefits include improved efficiency, reduced downtime, and increased safety. The post also outlines the key components of a SCADA system and how they work together to provide these benefits.